Gums, hydrocolloids, clean labels and the GMO factor: In conversation with CP Kelco

Speaking to FoodNavigator-USA after the IFT show in Las Vegas, where CP Kelco showcased a series of 4% protein beverage concepts using its stabilizers, technical service manager Wanda Jurlina said:

“We’ve seen a lot of growth from alternative dairy products where you need something to stabilize and suspend insoluble protein sources and insoluble calcium, which is often added to these products so they more closely match the nutritional profile of dairy milk.”

Cellulose gum, carrageenan

If you have a clean label, natural, or organic positioning, using a chemically modified cellulose gum is not ideal, she said, leaving you with a fairly limited set of options to help stabilize your beverage.

While carrageenan – which works well in such beverages - is not on the ‘unacceptable ingredients’ lists at influential retailers such as Whole Foods, meanwhile, some companies are nevertheless hesitant to use it, despite the lack of credible evidence (click HERE and HERE) to support the negative PR it continues to attract, she said.

“It’s a real shame as carrageenan [which CP Kelco extracts from red seaweed] has an amazing story, you’re supporting seaweed farmers and it’s very cost effective.”

Gellan gum

Gellan gum – which is produced by microbial fermentation (more on this later) – has a higher cost in use than carrageenan in such applications, but works very effectively, she said.

“One of the protein beverage concepts we showed at IFT, for example, was a chocolate drink made with a combination of pea and peanut protein where we used a gellan gum to suspend the cocoa, the insoluble components of the pea and peanut butter and also the fat [from the peanuts], and that beverage was really well received.

“We also had a UHT processed dairy-based caramel latte product fortified with calcium – which is insoluble and needs to be suspended throughout the beverage, throughout its shelf life.”

The great thing about gellan gum is that you can create “extreme suspension with a relatively light mouthfeel,” so you can suspend calcium throughout the shelf life without creating a thick gloopy texture, she said.

Pectin

In acidified UHT soy beverages, meanwhile, “pectin is very good at stabilizing soy protein at low pH during heat treatment,” she observed.

“Proteins are not normally stable at a low pH during heat treatment, but pectin can protect the proteins under those conditions and you can have a smooth and pleasant mouthfeel throughout the shelf life.”

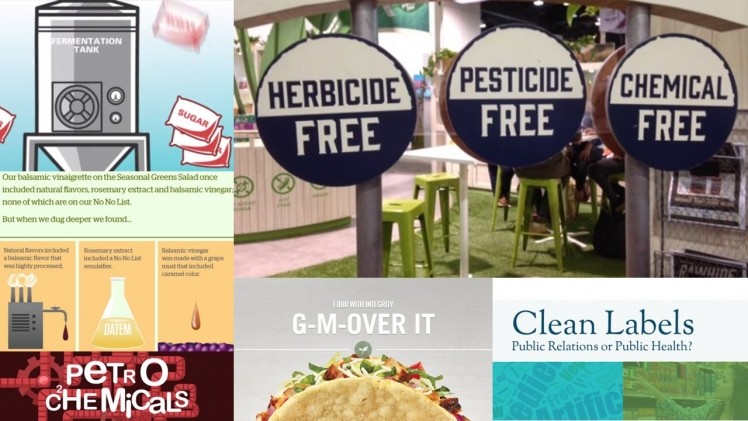

The GMO factor and hydrocolloids

When it comes to clean label claims, however, one of the biggest issues for the ingredients industry right now is the use of genetic engineering, she said, which can impact hydrocolloids such as xanthan gum and gellan gum that are typically made on a commercial scale via microbial fermentation (eg. a microbe converts sugars - the ‘feedstock’ - into the desired substance in a big fermentation vat).

“In Europe, for example, they look at the bacteria that produces the gum and if that is not genetically modified, then the gum is suitable for the market irrespective of what the feedstock is.

“With the growth of the Non GMO Project in the US, however, there has been a focus on feedstock, so we’re seeing more demand for products made with identify preserved feedstock [eg. not using GE corn or other sugar sources] for fermentation-derived products such as xanthan gum or gellan gum, even though the feedstock is typically a highly refined carbohydrate source so DNA is not present in the material."

For customers keen to avoid biotech at any stage of the production process, regardless of what’s in their finished products, she said: “We’re getting products Non GMO Project verified so our customers don’t have to go through the time consuming process of going through all of their ingredients directly with the Non-GMO Project and we’re aiming to have the bulk of our products verified by the end of 2017.

“We’ve already got a number of gellan gum products that are verified and we’re working on xanthan and pectin products as well.”

A two-tier system on non-GMO claims in the US

We are now seeing a two-tier system on non-GMO labeling, whereby some companies are making non-GMO claims based on whether they have ingredients derived from GE crops in their ingredients lists (eg. Chobani uses ‘non GMO ingredients’), while others are going one step further and drilling right down to the level of processing aids, feedstock for fermented ingredients, and even animal feed (eg. Dannon is now rolling out yogurts made with milk from cows fed non-GM feed), as required by the stricter Non-GMO Project verified scheme, she said.

According to Jurlina: “The approach that’s probably going to be more practical and cost effective is the Chobani approach, whereas going down to non GMO feed for livestock, that’s incredibly expensive to implement. They haven’t even gone to that extreme in Europe.”

Sugar reduction top of mind for customers

Another big growth area for hydrocolloids is sugar reduction, where gums and pectin can help to recreate the ‘full sugar’ mouthfeel of reduced sugar beverages in particular, she said.

“Sugar reduction is definitely top of our customers’ minds. They want to re-create the consumption experience and mouthfeel of a full sugar product with a 25% or a 50% or even a 100% reduction in sugar [high potency sweeteners such as stevia will only replace sweetness, not bulk], so we’re doing a lot of work on that.

“Say you’ve got a fruit flavored drink with 25% fruit juice and the control has maybe 10 or 12 brix, and the customer wants to reduce sugar by 25% or 50%, we can offer you three good options in terms of mouthfeel: pectin, xanthan gum and cellulose gums."

While you can also use polyols such as erythritol to recreate a ‘full-sugar’ mouthfeel, they are more expensive than hydrocolloids, where a small quantity goes a very long way, she said. “In the case of xanthan gum you might only need 200-300ppm, so it’s very cost effective.

When it comes to that much coveted ‘clean’ label, however, she said, pectin probably wins the day: “Pectin is by far one of the most label friendly hydrocolloids.

"Xanthan gum and cellulose gum are not on the Whole Foods and Kroger [unacceptable ingredients] lists, but there are always some customers that don’t want to use an ingredient that starts with an ‘x’ or they don’t want chemically modified cellulose gum, so it all depends on what your definition of clean label is.”

HYDROCOLLOIDS AND DIETARY FIBER: While the FDA is still deciding whether some hydrocolloids such as xanthan gum should be classified as dietary fibers, it's not keeping CP Kelco awake at night as customers are typically using these gums at very low usage levels for their technical function (eg. for stabilizing) and not in order to boost fiber levels, says technical service manager Wanda Jurlina.