Special Edition: Amino Acids and Protein

Animal feed sector likely first target for commodity algal proteins, expert says

The strategic push by the United States military establishment to have in-country alternative sources of jet fuel has provided a huge impetus to develop algae technology and production capacity. But it will be a while before that expertise and production capacity translates into large scale production of human nutrition ingredients, said Amit Vasavada, PhD, program manager of the department of alternative fuels at General Atomics, based in San Diego, CA. The animal feed markets will be the first that will likely see a big influx of commodity algal proteins, Vasvanda said.

Vasavada, who will speak on the subject of protein production from algae at the upcoming Algae Biomass Summit at the end of September in Orlando, FL, spoke with FoodNavigator-USA and NutraIngredients-USA on the near term future of the algae sector and General Atomics’ role in that development.

“General Atomics is a private company that has been involved in a lot of breakthrough technologies,” Vasavada said.

DARPA project

General Atomics, primarily a defense contractor best known in recent years as the producer of the Predator line of drone aircraft, got its start in energy product via nuclear power.

“We have been looking at energy independence as well,” Vasavada said.

“When our project started several years ago DARPA (Defense Advanced Research Projects Agency) funded us with several million dollars to find a low cost solution for fuel for the Department of Defense.

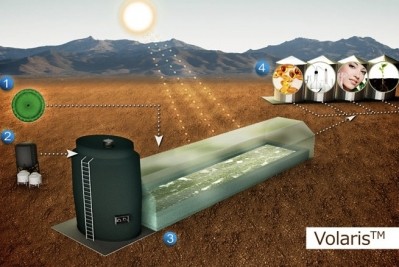

“You can make algae, you can make oil (from it), you can make jet fuel out of that oil. But at what cost? That’s the main driver. General Atomics believed that by using a systems engineering approach, we could come up with a novel solution. We developed technologies that would reduce the cost of fuel production when scaled up,” he said.

DARPA has funded a variety of such projects among technology companies, with some success. San Francisco-based Solazyme, for example, has already delivered hundreds of thousands of gallons of jet fuel in its pilot program.

Solazyme uses a fermentation technology, whereas GA in the DARPA program was investigating photosynthetic production methods. A fermentation approach would always have the added cost of an energy input via sugar to feed the organisms, while photosynthetic organisms derive their energy free from the sun. The calculation isn’t quite so simple, though, because fermentation delivers faster growth rates. Still, even with Solzyme’s proof-of-concept success, cost remains an issue.

“Fuel is a commodity product and it has to be very low cost. To reduce the cost of production you need to sell the leftover algae meal,” Vasavada said.

“When you put it all together, you need to have that revenue out of the leftovers. You cannot just throw it away. That’s when we realized that some of the strains we were working had extremely high protein content as well as other nutritional ingredients that could come in handy and that could make more money than the fuel by itself. We realized we could harness the same technology and produce protein and that could have an impact on world hunger,” he said.

Sustainability potential

But that impact would largely be felt through the application of algal proteins in aquaculture and in animal feed, Vasavada said. The production requirements are different enough between fuel and food that those resulting waste stream proteins would be more easily diverted toward feed, Vasvanda said. Using the leftovers in that way could make a difference in the sustainability of aquaculture in particular, he said.

“They are currently using fish meal in aquaculture. Can algae make a difference there? We believe it can,” Vasavada said.

Photosynthetic production methods always have the issue of contamination in open ponds, Vasavada said. For human nutrition, a closed system approach like Solazyme’s has some benefits in terms of tight control of the ultimate product.

“For human nutrition you have to think about quality. If you want to have something to feed to chickens or cattle or aquaculture, the level of stringency is much lower,” he said.

In terms of the big picture, it's likely that using algae directly to produce human nutrition ingredients will remain a niche application for years to come, Vasavada said.

"That part in my view is still coming. Not too many companies have really scaled up. The companies that have really scaled up are making high value products," he said.