Founded by chemical engineer Natalia Valencia and product design engineer Patricia Olave, the inspiration for the Valparaiso-based start-up came when Olave saw the thousands of tons of walnut shells discarded in Chile each year not as waste but as an organic raw material.

The antibacterial and antimicrobial properties of juglone, the molecule naturally present in walnut shells, are well documented in scientific journals but few manufacturers exploit this characteristic to make useful materials, Olave said.

Olave and Valencia began working together and, one month after setting up the start-up, received support from CORFO, a Chilean government agency of the Ministry of Economy, Development, and Tourism.

Innovation in a nutshell

The Valnux material is compostable, meaning it fully disintegrates and decomposes, and does not alter the organoleptic properties of the food. The scientists-turned-entrepreneurs have tested and confirmed the antibacterial and non-toxic properties of the Valnux material in microbiology laboratories.

“The process uses the plastic traditional infrastructure, but the Valnux material is a bio-plastic from vegetable sources only, agglomerating crushed shells into previously designed and fabricated molds,” Olave, Valnux's CEO, told FoodNavigator-LATAM.

The final product is a biodegradable thermoplastic, meaning it can be recycled by subjecting the material to high temperatures – although this also limits its use as it becomes pliable at certain temperatures.

Co-developing 'any product industry needs'

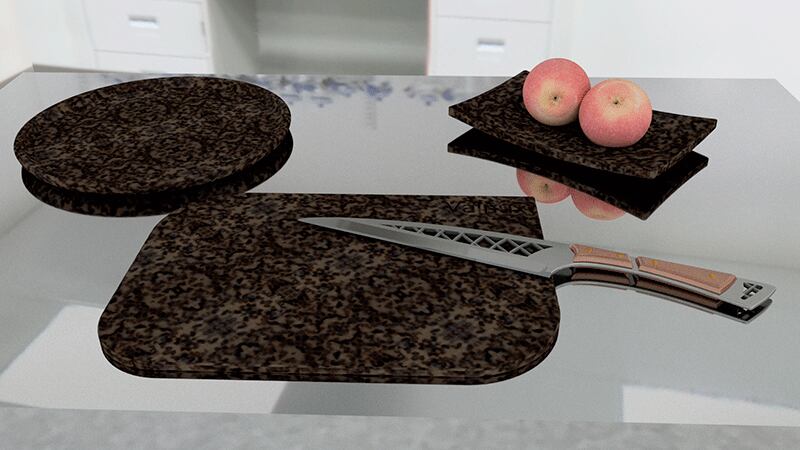

Valnux’s first products are B2C kitchen utensils such as chopping boards and fruit bowls but Olave and Valencia believe the material has wider, industrial applications, such as food packaging, and are open to co-developing “any product that industry needs”.

“We have different industrial possibilities for this material, but for food [applications] it is necessary to keep investigating properties like the permeability of gases or UV filtering. And to be coherent with the ecological purpose of Valnux, this must come from natural components," said Olave.

The company can produce over 30 medium chopping boards using the by-products from one hectare of walnut production in one season.

According to Valnux, Chile is the second biggest walnut exporter in the world – less than 5% of its production is destined for the domestic market – and, in 2018, more than 12,000 tons of walnut shells were left in the country.

The majority of this waste is currently burnt as an alternative to firewood or used to replace groundcover in gardens.

According to data from the United Nations’ Food and Agriculture Organization (FAO), Chile produced 81,163 tons of in-shell walnuts in 2017, making it the seventh biggest producer in the world, behind China, the US, Iran, Turkey, Mexico, and Ukraine.