Founded in 2018 by biotechnology entrepreneurs Halim Jubran and Tal Zeltzer, Israeli start-up Phytolon is on a mission to ‘revolutionise’ the natural colours industry.

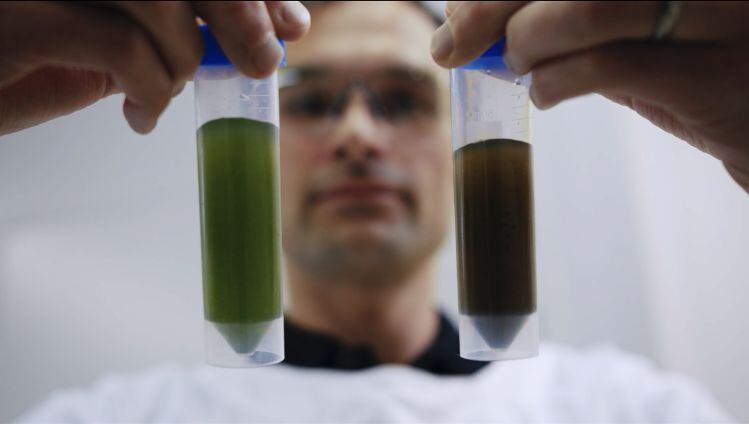

Rather than source natural colours from fruits, vegetables, and plants, or make synthetic colours from petrochemical sources, Phytolon is turning to precision fermentation.

The result is a range of stable natural colours covering the full yellow-to-purple spectrum.

Precision fermentation-derived betalain pigments

To date, hundreds of artificial food dyes have been developed by converting petrochemicals, via synthetic chemistry, into a wide range of colours.

As consumers increasingly seek out more sustainable and ‘natural’ products, Phytolon is responding with solutions that offer equivalent pigment vibrancy, but which come from biological – rather than petrochemical – sources.

The start-up has developed a patented process for producing betalain pigments through precision fermentation of certain yeast strains. The process, it says, is as simple as brewing.

What are betalains? They are natural pigments responsible for colouring some of the most vibrant plants on the planet, for example in beetroot and cactus fruit. The water-soluble pigments retain colour stability at wide pH range, as well as when exposed to heat and light.

In leveraging precision fermentation technology, Phytolon is also working to disrupt the natural colours sector, which relies on pigments derived from fruits, vegetables, and plants.

The start-up’s novel production technology requires less land use, water use, and has a reduced carbon footprint compared to conventional natural pigment manufacture, Phytolon suggested.

The uniqueness of Phytolon’s technology, according to co-founder and CEO Halim Jubran, is that once the colours are produced in the cells of the yeast, the colours are ‘spontaneously’ released out of the cells – resulting in cell-free and DNA-free pure natural colours.

This means that they qualify for GMO-free classification in the US and Europe, we were told.

“Phytolon’s colours were demonstrated as highly compatible with alternative meat and dairy in terms of colouring performance,” Jubran told FoodNavigator. “Also, Phytolon’s offering goes in harmony with the offering of these innovative markets in terms of sustainability.”

Phytolon partners with Ginkgo Bioworks

To take Phytolon’s innovation to the ‘next level’, the start-up has announced a collaboration with US biotech Ginkgo Bioworks, a leading horizontal platform for cell programming.

Under the partnership, Phytolon will leverage Ginkgo’s ability to engineer biology at scale, and work together to produce vibrant cultured food colours via yeast fermentation.

“The collaboration will yield production of the full yellow to purple spectrum, including all yellows, oranges, reds, pinks, and purple, in accordance with Phytolon’s IP for commercial use of bio-produced betalain colours,” explained Jubran.

“This spectrum covers 75% of the market demand for food colours.”

Jubran’s co-founder and Phytolon CTO Dr Tal Zeltzer, said the start-up was ‘excited’ to work with Ginkgo to develop natural colours that have the potential to outperform conventional artificial dyes in cost and performance.

“We believe biotechnology makes it possible to produce a wider range of colours than ever before that may outperform current benchmark colourants, and we look forward to building products that may meet and even exceed consumer expectations for healthier, sustainable foods, all the while aiming to maintain industry requirements for high quality and cost-efficiency.”

From Gingko’s perspective, the biotech is looking forward to helping Phytolon ‘challenge industry norms’ and ‘attempt to build a fundamentally better product’ than what’s on the market today.

“The planet needs new sustainable solutions, and we are excited to partner with Phytolon to support a more sustainable food system,” said Jennifer Wipf, head of commercial, cell engineering, at Ginkgo Bioworks.

Preparing for 2023 launch

Phytolon is expecting its precision fermentation derived colours to reach the market next year, in 2023. Relevant food applications include meat, plant-based meat, bakery, confectionery, dairy, frozen and confectionery.

How will these pigments appear on ingredients labels? FoodNavigator asked CEO Jubran: “The colours can be called, for instance, ‘fermented betelain colours’, or ‘betelains from fermentation’.

“Most importantly, they will still qualify the ‘natural’ label and/or the non-synthetic label of food products that they dye.”