No baby food manufacturer intentionally adds heavy metals to its products: arsenic, cadmium, lead, and mercury are naturally occurring. The crops absorb the heavy metals from soil and water, which is how they end up in baby food. Nevertheless, it is the company’s responsibility to ensure that the ingredients and the finished products have a safe heavy metal limit.

Tackling the heavy metal problem is not as daunting as it might seem.

Company employees can considerably reduce the chances of arsenic, cadmium, lead, and mercury lurking in their baby food in dangerous concentrations by making sure the crops are grown with natural soil additives, sourcing cereals, fruits, and vegetables from low-arsenic fields, ensuring the farmers who grow the sourced crops alter irrigation practices, preparing the baby food in the facility with excess water to get rid of the extra arsenic, and blending high-arsenic grains, such as rice, with low-arsenic grains in multigrain products.

Testing baby food for heavy metals must become a critical practice

Testing baby food for heavy metals is very easy and cost-efficient today. It should become standard practice at the facility, which will ensure that companies will not allow products with high concentrations of heavy metals on the shelves.

While having a sample of baby food tested for arsenic, cadmium, lead, or mercury costs between $50 and $100, manufacturers will undoubtedly obtain a good deal with a reputable laboratory that will benefit both.

Additionally, every baby food facility that must comply with the Food Safety Modernization Act (FSMA) must also implement Hazard Analysis Critical Control Point (HACCP) and set up preventive controls.

Recognized internationally, HACCP ensures the safety of consumers by avoiding toxic agents in food. Baby food manufacturers should focus on chemistry testing, as it addresses chemical and physical hazards, including heavy metals.

Alternatively, they can test their products using the guidelines of the Environmental Defense Fund. This non-profit advocacy group advises baby food manufacturers to prohibit arsenic, cadmium explicitly, and lead in any packaging or food-handling equipment.

Baby food companies should test the ingredients, the products per se, and the packaging for arsenic, cadmium, and lead.

Finally, baby food companies should examine the potential sources of heavy metals where measurable concentrations were found and periodically test baby food and its main ingredients by using the method approved by the FDA.

Testing the packaging that touches food anywhere along the supply chain for arsenic, cadmium, and lead through a CPSC-accepted, third-party certified lab that evaluates baby food for heavy metals is also extremely important if companies want to have a concentration of toxic metals in their products as close to zero as possible.

If the heavy metal concentration exceeds the safe limit in baby food, the best course of action is to issue a recall on the adulterated lots as soon as possible.

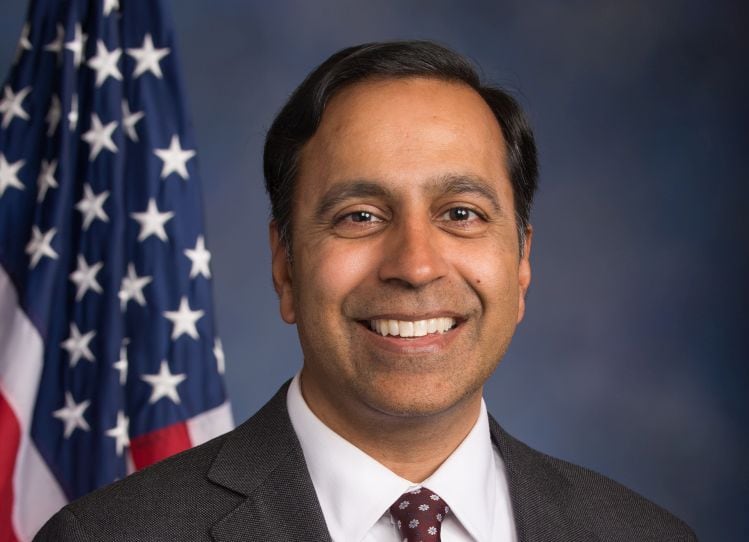

Jonathan Sharp is the chief financial officer at Environmental Litigation Group, P.C., a law firm, headquartered in Birmingham, Alabama that specializes in toxic exposure. Jonathan Sharp oversees financial analysis, collecting and distributing the funds, case evaluation, management of firm assets, and client relations.