Nearly two years have passed since PepsiCo’s Quaker Oats was hit with a massive salmonella recall that threw it into a tailspin, but the nearly 150-year-old brand is rebounding with a charm offensive focused on social media influencers and products that cater to increasingly savvy consumers.

The recall, which began in late 2023, resulted in more than 60 separate product lines, and an untold number of units, being pulled from store shelves, and ultimately led to the closure of its plant in Danville, Ill., where the products were manufactured.

It drove a 20% year-over-year drop in volume in the second quarter of 2024 and hit PepsiCo’s bottom line hard, shaving off 60 basis points from the company’s total organic revenue growth for the quarter.

Beginning in 2025, PepsiCo for the first time combined the financial results of its two food divisions – Quaker Oats and Frito-Lay – as PepsiCo Foods North America and reported in the second quarter that “organic volume trends improved versus the previous quarter as we accelerated our agenda to improve our marketplace performance and reduce costs.”

Now in its effort to right the ship, the world’s largest manufacturer of oats is courting social media influencers, focusing largely on recruiting registered dietitians and their hoards of loyal followers to help spread the message.

Not your parents’ oats

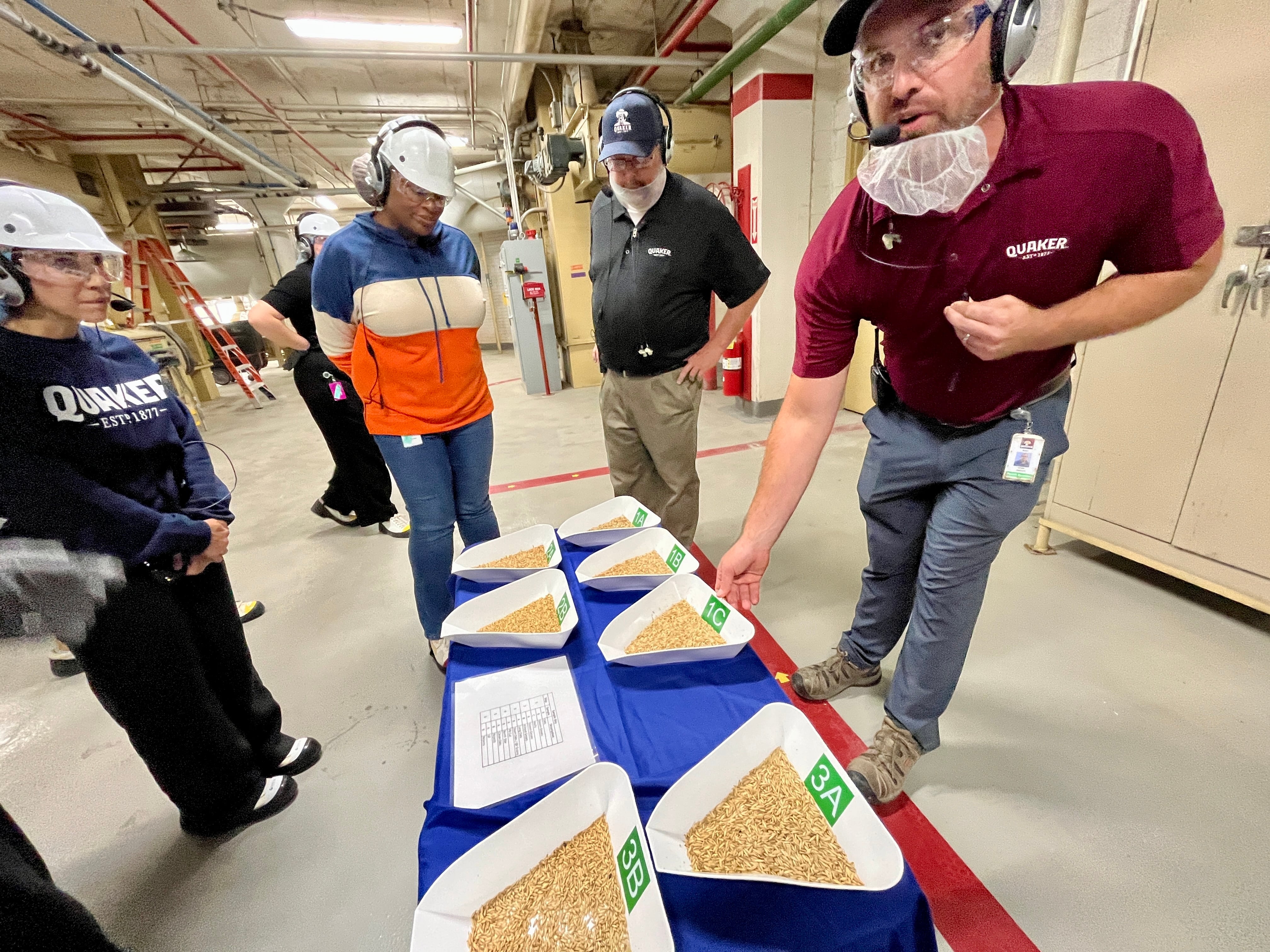

In September, Quaker Oats sponsored a press junket of mainly TikTok-famous dietitians to its flagship manufacturing facility in downtown Cedar Rapids, Iowa, one of five Quaker Oats plants in North America and the largest milling facility in the world.

The mill has burned to the ground twice since first opening as the North Star Mill in 1873, less than a decade after the end of the United States Civil War.

The Cedar Rapids mill is the site where Quaker Oats developed its iconic round canisters in 1915, its Quick Oats in 1922 and its Instant Quaker Oatmeal in 1970. The facility processes over 2 million pounds of oats a day and continues to innovate with products like Mighty Life Healthy Bone Support and Mighty Life Immunity Support cereals, both released in April, and its Quaker Protein Instant Oatmeal, which includes no added sugar and 10g of protein per serving.

The two new breakfast items, while not highlighted during the recent mill tour, are among the new products in the company’s effort to appeal to a new generation of health-conscious consumers, many of whom turn to registered dietitians and other influencers on social media for advice.

Baking with oats

The mill tour – attended by FoodNavigator USA, eight registered dietitian influencers and celebrity chef and restaurateur Tiffany Derry – was bookended by meals and a cooking class that illustrated the ability to use Quaker Oats products for baking and cooking.

Attendees were treated to specially-made dishes with chef-inspired creations, including: Crunch Town Fish Nuggets, deep-fried, seasoned white fish breaded in Cap’n Crunch with sriracha tartar; meat loaf made with Quaker Oats Old-Fashioned Oats; and a side salad with mixed kale, red leaf lettuce, crushed Quaker Oats Oatmeal Squares and dried cranberries.

Following the mill tour, Quaker Oats hosted a lunch that featured another range of Quaker Oats-inspired dishes that included Cornbread made with Quaker Yellow Corn Meal; apple crisp made with Quaker Oatmeal; and Quaker Rice Cakes topped with bite-sized sweet and savory toppings.

The main course – pork ribeye cutlet breaded with Quaker Cinnamon Life Cereal and topped with grilled peach compote – was made by the attendees themselves under the guidance of a chef.

On its website, Quaker Oats offers nearly 600 recipes that includes a wide range of dishes that go beyond the typical oatmeal cookie or bran muffin. Some examples include garden pizza, stuffed turkey burgers, grit cakes with zucchini and steel cut oatmeal risotto with prawns.

Ultimately, the company aims to convey the message that Quaker Oats is more than just a breakfast company.

The mill tour

The Quaker Oats-inspired dishes were just an appetizer for the main course: a half-day tour of the 120-year-old mill.

Despite its age, the Cedar Rapids facility continues to innovate its manufacturing processes; and although Quaker Oats opened much of the facility to photos and videos, the company noted that some areas of the tour were off limits for social media. The food manufacturer faces fierce competition in the industry, particularly from its cross-town competitor, General Mills, which also operates its largest manufacturing facility in Cedar Rapids.

Mark Tonne, senior site director at the mill, said the Cedar Rapids plant is one of PepsiCo’s largest manufacturing facilities, claiming more than 240 silos and the ability to mill about 80 acres of grain per hour, most of which is shipped in by rail from Canada.

“You’ll find a Cedar Rapids component in about 70% of all of Quaker Oats’ products,” he said. “Whether they’re made here or in a sister facility or a co-manufacturer, about 70% of them have at least an ingredient or component that’s made here in Cedar Rapids.”

Gluten-free tech

Quaker Oats has been offering gluten-free products for about a decade now, and the company is growing increasingly efficient at making them.

Joe Griebat, milling senior manager at the plant, said the company sets a high standard on gluten-free products. But that can be a challenge with farmers growing products in fields adjacent to those growing barley, wheat and rye, which causes contamination.

“We can make gluten-free as good as everybody else in the FDA standards, which is like 20 parts per million on average across an entire lot of product, but we dedicated ourselves to making it zero,” he said. “We thought, if you have Celiac and you choose Quaker Oats, there’s going to be zero gluten contained in it.”

Over the last decade, Quaker Oats has pioneered using a computer-operated infrared light scanner to detect any impurities that would taint the gluten-free product. “You can’t tell with your own eyes, but in the infrared, the computer can tell,” Griebat said.

Quaker Oats has continued to fine-tune the infrared scanner to speed up the search for gluten impurities. “Now it runs through there so fast, you can’t see the space between the oats,” he said.