Used since the Stone Age in Africa, acacia gum improves the stability and texture of food products.

In today’s world of food innovation, it delivers myriad benefits from emulsification to thickening, while enhancing fiber content. Alland & Robert has been continually focused on innovation in acacia gum, most recently investing more than two years of effort to improve both its functionality and sustainability credentials, yielding Beyond Acacia®.

Tracking gum acacia back to the source allows a unique perspective on the full value chain, and the opportunities to address the pillars of sustainability – planet, people and profit. Across the Sahelian zone of Africa, native acacia trees offer a natural defense against the advance of the desert. Its deep roots can span up to six times the height of the tree, fixing the sandy soil, while its leaves improve the soil’s fertility and nitrogen content. There are multiple species of acacia. However, according to Food Codex, acacia gum can only come from two varieties of acacia trees: Acacia senegal and Acacia seyal.

At the start of the dry season, around October, villagers across the region – from Sudan and Senegal to Ethiopia and Chad – tap the acacia trees, removing strips of bark to expose the inside of the branch to the arid climate. Over the next several weeks, the tree produces an exudate that covers the incision to prevent moisture loss, microbial and insect attacks; those nodules, warmed by the sun and dried in the wind, are hand-picked by the farmers. It is estimated this wild harvesting yields between 80,000 and 90,000 metric tons of gum acacia annually, running until the start of the rainy season around April, when the farmers turn to food crops.

Offering farmers an off-season way to increase income has enhanced the economic well-being of those in the gum acacia communities. Alland & Robert has invested in social and environmental sustainability programs. Through its Corporate Foundation, the company has invested in initiatives to develop infrastructure in harvest areas; support local communities through projects related to education, health, and female empowerment; and preserve the Sahelian environment.

Further, through a partnership with the NGO Tree Aid based on the volume of gum acacia sold by Alland & Robert, the foundation has funded the planting of more than 18,000 native trees in several Sahelian countries since 2020. Finally, Alland & Robert received the first-ever FAIR FOR LIFE (FFL) certification from Fair Trade Ecocert for its senegal and seyal gum acacia, which guarantees the products come from environmentally friendly processes practiced by fairly paid farmers, from a transparent and traceable supply chain.

The importance of rehabilitating the landscape and empowering local populations through collaboration cannot be understated. The World Meteorological Association estimated in its State of the Climate in Africa 2023 report that climate change is responsible for a loss of approximately 3% of agricultural GDP annually in sub-Saharan Africa. Capitalizing on local farming of acacia trees offers economic diversification for farmers, while simultaneously fighting desertification.

Optimizing production for market differentiation

As a highly safe ingredient used for many centuries, acacia gum offers numerous functional properties and is today found in thousands of everyday products. From ancient usages in Egypt to today’s use in beverages, the story of acacia gum is remarkable. It is valued for its emulsification properties, supporting stabilization of processed foods, while also improving texture and functioning in some food matrices as a processing aid. Its ability to form films and encapsulate particles makes it useful in flavors and coatings. It also serves as a highly soluble fiber source (more than 90% fiber content), and can be used as a bulking agent.

After harvest, the nodules of raw acacia gum are dried and sorted to withdraw foreign matters that could be a source of contamination. The nodules are then shipped to the Alland & Robert factories in France. After quality control, batch selection and definition to optimize gum usage, the nodules are kibbled to facilitate solubilization in water.

After several purification steps, including decantation, centrifugation and filtration, the acacia gum is transferred into a spray drying tower to allow quick evaporation of water. Spray dried acacia is the main form used globally, and the process of spray drying involves high temperatures (around 380 degrees F), generally powered through natural gas. Once these steps are completed, the yield is an off-white, fluffy powder.

In examining its own Greenhouse Gas (GHG) emissions, Alland & Robert prioritized improvement of energy performance during the manufacturing process, while also exploring how to yield a more unique functional gum acacia ingredient.

Charles Alland, CEO and president, says: “Our heavy investments reflect our commitment to manufacturing sustainable, natural and low carbon products. Offering environmentally friendly products is part of our corporate social responsibility plan and our sustainability targets.”

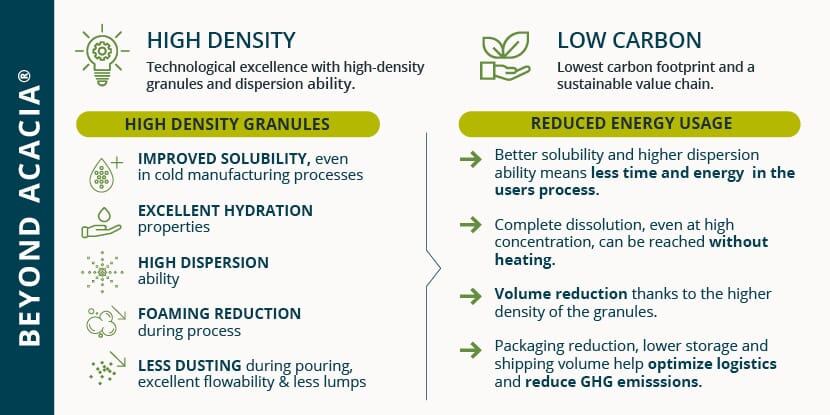

Instead of traditional spray drying, the company turned to fluid-bed drying, commonly used in the food industry for temperature-sensitive compounds or for encapsulation. Using lower temperatures and constant tumbling, the process yields higher density granules; the dryer also runs on electricity from sustainable green energy at Alland & Robert’s facility in France.

In addition to reducing energy consumption and utilizing more electricity than gas, the volume for net weight is significantly reduced, dropping shipping and storage volume. The volume of Beyond Acacia® for a net weight of 100 grams is only 170 ml, a 23% volume reduction compared to spray-dried and 32% volume reduction vs. instant soluble gums.

Application ease yields sustainability benefits

Using the fluid-bed drying technique preserves the functional properties of gum acacia; once dissolved, quality is identical to regular and instant gum acacia. However, there are multiple benefits during production that impact companies’ own sustainability measures, as well as optimize production.

“Beyond Acacia® allows R&D teams to review their production process to decrease processing time and increase output,” explains Michael Sutich, director of business development, Farbest.

“The ingredient’s granular particle size allows for maximum use of all material purchased, saving procurement groups money by limiting ingredient loss during processing. Ultimately, this improves sustainability measures while delivering exceptional performance.”

From a waste management perspective and ease of use, the granular gum is easier to pour than traditional powder, eliminating product lost to dust from its flowability. In addition, the high-density granules create less foam during production, requires less powerful stirring and allows, if applicable, solubilization at room temperature, leading to energy savings.

In addition, there are multiple benefits including improved solubilization (even during cold manufacturing), excellent hydration properties, high dispersion ability, reduction in foaming, and less dust during pouring due to excellent flowability and fewer lumps. The increased wettability means the high-density granules are faster into solution, even at lower temperatures. And on an energy basis, while traditional powder requires high-speed mixing, the granules dissolve at lower speed, reducing energy consumption.

As companies look to improve their own GHG emissions, this new solution can impact all levels. An independent consulting firm specializing in carbon emissions found that compared to standard acacia gum, Beyond Acacia® offers a 51.1% decrease in direct and indirect emissions, and a 13.5% decrease in emissions up and down the value chain. This is part of a commitment by Alland & Robert to reduce by 20% all GHG per kilo of manufactured gums between 2020 and 2025.

Countries and governments around the world are looking more closely at sustainability issues, and producers have the opportunity to address current and potential regulatory requirements around GHG emissions and other sustainability considerations. Marrying that forethought with the ability to charge product innovation with the unique functional qualities of Beyond Acacia® offers food and beverage manufacturers a win-win situation.