Speaking to FoodNavigator-USA for our flavor trends special edition, Conagen VP R&D Casey Lippmeier said that when we think about how natural ingredients are going to be sustainably sourced in future, we may need to reassess current approaches.

"A flavor compound might comprise something like 0.001% by weight of the whole plant, so really a fractional, trace amount, yet you’re still using land and water and energy to grow the whole plant, whereas if you make it by microbial fermentation [eg. Inserting DNA sequences into a microbe such as yeast, bacteria, fungi or algae to instruct it to produce any given flavor during a fermentation process with sugars as the feedstock] or bioconversion [where you start with a plant extract, say, but then use enzymes to convert that into a target molecule], you can significantly increase your efficiency and yield of production on a per acre base dramatically – plus you’re not using all the fertilizer, pesticides, water, and so on.

"You still need to feed the microbes some kind of energy source – typically some kind of sugar – usually from corn or sugar cane, but they are the most photosynthetically efficient plants on the planet."

If you’re making flavors in fermentation tanks, meanwhile, you can make them to order, and you don’t have to worry about unpredictable weather, seasonality, political instability, supply chain interruptions, heavy metals and unexpected pesticide residues that plants suck up from the soil, he added.

"I think synthetic biology and fermentation science is going to become much more important for making a lot of our everyday products, from nutritional ingredients, flavors, colors, sweeteners and natural preservatives to detergents."

The building blocks of flavor

But is the flavor made in a fermentation tank the same as the flavor extracted from a plant?

Flavors are made from multiple components, which flavor scientists combine to deliver the final product, and you can create the building blocks of these using fermentation, said Lippmeier, noting that the three key components of peppermint oil - menthone for scent, menthol for cooling, and germacrene for flavor - can all be created via fermentation.

“When you’re producing a substance in a process that’s engineered, although still inspired by nature, you can make a much more pure product, and that is desirable to formulators because then you can custom blend your flavor ingredients however you like, and reduce off flavors.”

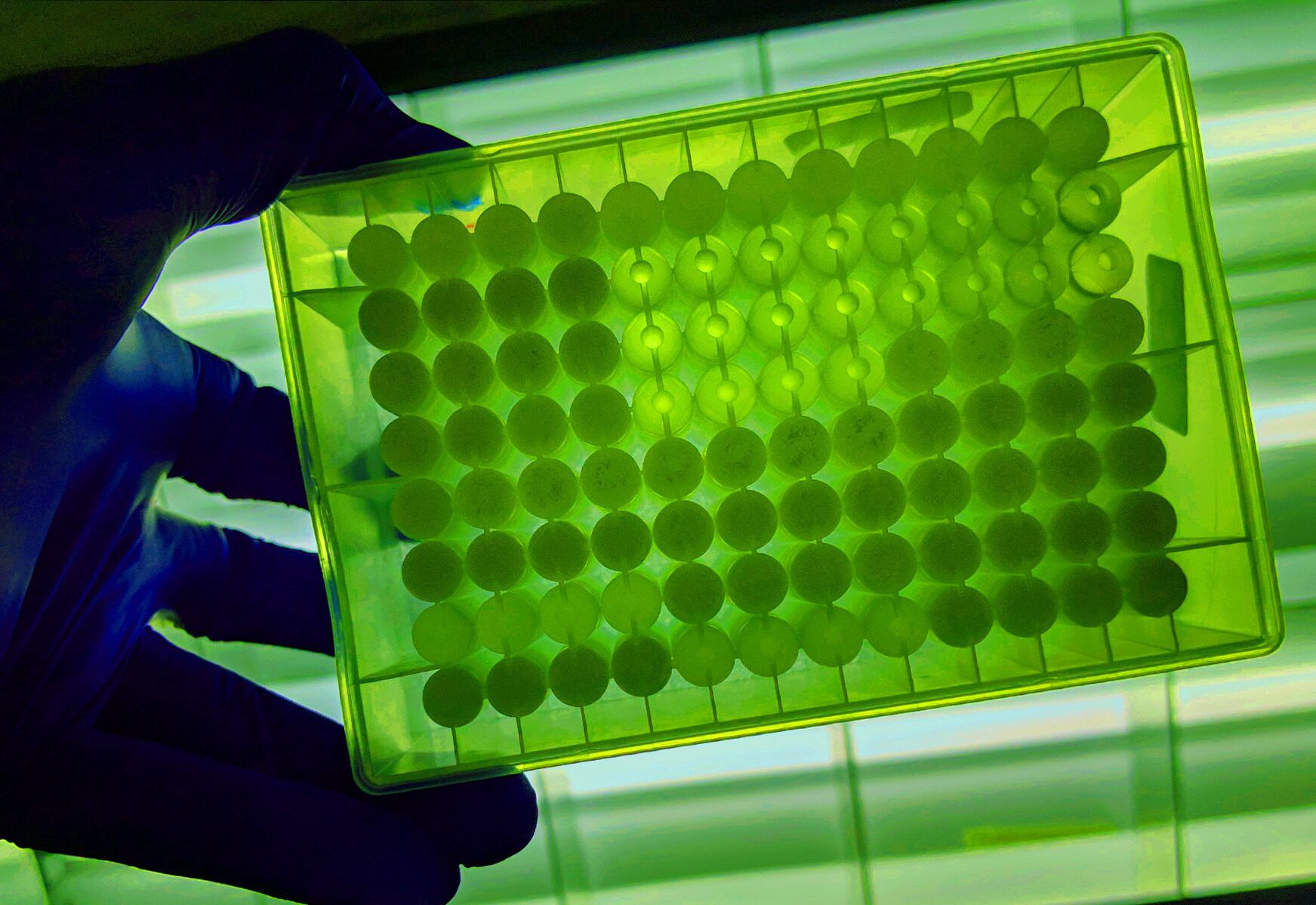

What is synthetic biology? Pioneers in the space liken synthetic biology to computer programming, only with genetic sequences. DNA is effectively serving as a computer code (which can be now be printed surprisingly cheaply) that can be inserted into microorganisms such as yeast and bacteria so they express proteins, sweeteners, flavors, cannabinoids such as CBD, or basically whatever you have ‘coded’ or ‘instructed’ them to produce.

‘We’d like to replace all of that synthetic vanilla market with our product’

Vanilla is an interesting case study, he says. Right now, 90% of the vanilla flavor used in food and beverage products is vanillin that’s made ‘synthetically’ from the petrochemical constituent guaiacol, because demand massively outstrips supply when it comes to vanilla seed pods grown in Madagascar.

However, vanillin can also be made ‘biologically’ from ferulic acid (derived from rice bran) via a fermentation process using a naturally occurring 'wild type' yeast, or from a genetically engineered microbe (baker’s yeast) and sugar, which both deliver a different flavor experience to ‘artificial’ vanillin, he said.

“Vanilla is #1 best-selling flavor molecule globally and 90% of it is synthetic, and if we’re being really ambitious, we’d like to replace all of that synthetic vanilla market with our product, so customers using our vanillin [from ferulic acid in partnership with BASF] can use the term ‘no artificial ingredients.’”

Meanwhile, if you also want some of the complex notes (smoky, spicy, botanical, sulfury, sweet, creamy, medicinal, cooked, fatty, and floral) associated with vanilla bean extract (which contains multiple components in addition to natural vanillin), you can create these via fermentation and build up your flavor as with peppermint, he explained.

I generally think of natural as anything that’s made biologically

But what about ‘naturalness’? Are flavors produced in fermentation tanks as ‘natural’ as those extracted from plants?

“I generally think of natural as anything that’s made biologically," said Lippmeier, "because the molecules that you make from biological processes, regardless of the organism, come out the exact same structurally, and that is demonstrably not true when you make them with chemistry."

‘We have more platform organisms than any other synthetic biology platforms in this space’

So how challenging is it to produce food ingredients via ‘bioconversion’ or microbial fermentation – something that’s now being deployed to make everything from proteins and fatty acids to sweeteners, flavors, colors and cannabinoids?

“To do this you need well-trained fermentation engineers, enzymologists, synthetic biologists, biochemists and molecular biologists, so there are barriers to entry,” said Lippmeier.

"So right now this [microbial fermentation and bioconversion] probably accounts for less than 5% of the [flavors] market. However, the technology has matured to the extent that we can be very precise with the biology now, and computational power is a big part of what has enabled that precision.

"We also use a lot of artificial intelligence for designing our particular processes and enzymatic reactions, but also on the demand side, you hear stories every day that we're running out of land, so if we can make products in a more efficient way, the demand for that will only increase."

As for what makes Conagen stand out, there is room for multiple players in the microbial fermentation space, he adds, but “with that said, as far as we’re aware we have more platform organisms than any other synthetic biology platforms in this space.

“We have 14 different platform organisms now and we’re about to add another six, spanning the whole menagerie of microbes.”

Conagen provides the science underpinning products it sells directly or via affiliates such as Sweegen, Blue California and BASF. Its flavor and fragrance development and manufacturing capabilities include:

- Mint flavors and fragrances

- Fruit flavors from lactones – peach, strawberry, orange, vanilla, coconut

- Orange peel fragrances and flavors

- Hot pepper spice from capsaicins

- Sandalwood scent

- Floral fragrances from terpenoids and carotenoids – rose and violet scents

- Natural colors from flavonoids and carotenoids – orange, red, yellow, purple

- Natural vanillin in collaboration with BASF

- Reb D +M steviol glycosides in collaboration with Sweegen

- Various nutraceuticals

- Natural preservatives