“In the beginning, like a lot of people, we just went out, bought some crickets, and started raising them in a small room, but the bridge from being a small startup to going industrial is super challenging.

“We’ve made that jump and we’re on the other side, so production costs have started to go down and now we have a much better understanding of the density [of crickets that can be sustained in a farming operation], the different temperatures, the humidity, the kind of feed and pretty much everything crickets need.

“However, we've been lucky enough to find the right partners that support what we’re doing.”

But there’s no playbook, he said, and many entrepreneurs in the field have simply “run out of money, energy or enthusiasm… Raising crickets is an extremely complicated task and I totally understand why companies have gone out of business.”

‘I totally understand why companies have gone out of business’

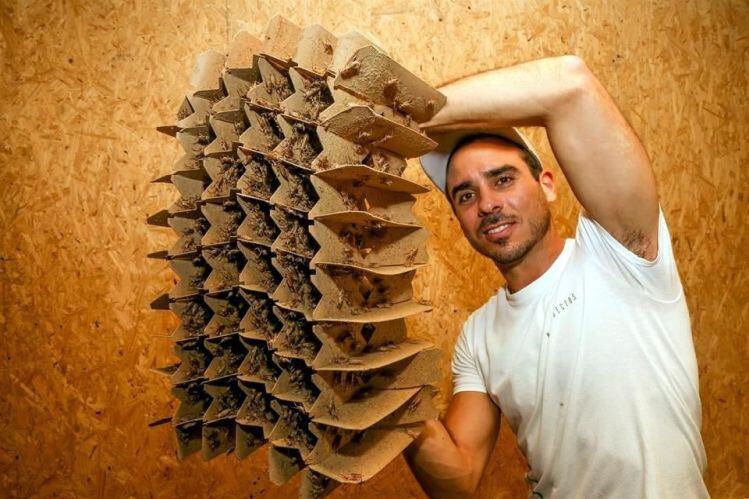

Today, Nutrinsectos has two farms in Guadalajara (3,000 square meters and 600 square meters) producing cricket protein primarily for the North American market, with 50% of production is going to petfood and 50% to human food, typically small CPG brands making developing snacks, protein bars, or shakes.

The two main costs of running the operation are labor and feed, says Jimenez, with efforts underway to automate some processes, although feed costs are more challenging. As Aspire Food Group Gabe Mott told us in part II of our series, you can feed crickets a wide range of things, including post-consumer waste, but replacing a modified chicken feed diet with food waste or other cheaper or more sustainable options can present challenges around safety, hygiene and consistency of the end product, he says.

“For now we give them a dry diet based on seeds and cereals, with water on the side.”

‘We’re pretty confident that Nutrinsectos is the largest cricket farm in Latin America’

So when it comes to scale, can you still make money as a medium-scale producer? Is there a profitable middle-ground between a large, automated facility of the type that Texas-based Aspire Food Group is building in Canada, and a hobbyist operation that can support a small CPG brand, but not much else?

“Of course everyone recognizes Entomo Farms and Aspire [the two largest suppliers of cricket protein in North America]," says Jimenez. "But we’re pretty confident that Nutrinsectos is the largest cricket farm in Latin America and we’re focusing on production so our customers and business partners can develop the best products and brands.

“But if your desire is to ultimately compete with beef, chicken, fish, or pork, I believe the only way to get to those costs production costs is by producing huge amounts of powder. But before jumping into that stage, there is still a fairly good market [for firms such as Nutrinsectos] as companies are willing to pay a little more for the kind of quality products we produce.”

Frustrating lack of consistency

Right now, he claims, there is still a frustrating lack of uniformity in supply, such that if a US protein bar brand, for example, were to order a pound of cricket powder from 10 different suppliers, it would still get 10 different products.

“Even though cricket powder might look the same online, they all have different qualities and characteristics, a different nutritional profile depending on what they have been fed, and also the safety of the product because the way they they've been farmed.”

‘Big Cricket Farms was a rather bruising experience’

Indeed, while players such as Nutrinsectos, Aspire and Entomo are making high-quality consistent products from food grade facilities, it can be a bit of a crapshoot if you’re buying from an untested source, says Kevin Bachhuber, an insect agriculture consultant who has also been there, done that, and bought the teeshirt when it comes to raising crickets for food.

“The one that always sticks in my memory was where a client brought in a couple of hundred kilos of cricket powder from Thailand and it had all these little tiny red rubber balls in it because the grinder [for milling the crickets] was too close to a shelf that shaken a bag of rubber beads into the mixture," recalls Bachhuber.

"But I don’t want to make generalizations about Thailand because there are companies out there such as Cricket One that are setting the standard in terms of quality.”

‘When we all started, a lot of us didn't really know what we're doing’

Bachhuber’s first foray into farming, Big Cricket Farms in Ohio, was aborted in 2015 owing to problems with heavy metals in the water supply, but he has recently jumped back into the fray with the launch of a new facility in Madison, WI (Madison Cricket Farm) supplying live crickets to pets, which right now is more lucrative than trying to supply humans, he says.

“Big Cricket Farms was a rather bruising experience, and fairly public, too, but in January of this year, I started Madison Cricket Farm, and for the live feed market there’s a screaming amount of demand right now.”

Echoing Jimenez’s point, he adds: “When we all started, a lot of us didn't really know what we're doing. But at this point, if you're still in business, you definitely know what you're doing.”

Entomo Farms: ‘There's no doubt that for our business, the pet food category is accelerating the quickest’

Clearly, edible insects for the human food market have not taken off in the hockey stick fashion that some commentators predicted they might a few years ago, acknowledges Jarrod Goldin, co-founder at Entomo Farms, a leading supplier of cricket protein based in Ontario, Canada.

“There's no doubt that for our business, the pet food category is actually accelerating the quickest, we have great customers all over the world, but particularly in the US. One of our customers – Jimimy’s - now has a product in Petco, and we’ve also signed a deal with a major Canadian retailer that’s going to distribute cricket frass [poop] as an organic fertilizer under their private label brand.”

He adds: “There are a lot of companies now working with black soldier flies or mealworms for livestock feed or for the frass.”

That said, the human food side of the business is still progressing, he says: “We’ve just launched a brand called Actually Foods starting with three flavors of cheese puffs with 9g protein [billed on the website as ‘powered by sustainably farmed, organic crickets, our puffs are high in protein, rich in vitamins such as B12, and a natural source of prebiotics…’]

“But I’d be remiss if I didn’t say that the human food side has been slower. I think we need to give people more than just a sustainability reason to consider this protein alternative, and that's going to take more work and research.

“There’s a positive impact on the gut microbiome from studies that have been done and we have a big B12 study we're about to do, as well as a really interesting study with Dr Joel Mason at Tufts University, and that is going to be looking at possible impacts of an insect-based diet on colorectal cancer in mice."

‘Crickets are high in protein, fiber, and B12’

However, there is already a lot to work with when it comes to nutrition, he adds: “Crickets are high in protein, fiber, and B12, which we can already talk about, and cricket powder is a whole unprocessed food [milled whole crickets], and I don’t see the other proteins out there as sustainable or as healthy.

“So I think that as we build clinical, nutritional, and medical value for crickets as a protein alternative, and more companies offer pasta, protein bars, cheese puffs, crackers, chips with that protein, and those products are easy to find and more affordable, and we’ve scaled up production to bring unit costs down, we will continue to grow slowly…

“We certainly hope to be close behind Aspire for what we call our phase II to move out of these retrofitted chicken barns into something far more industrial.”

As for consumer brands, while many startups using crickets have thrown in the towel, he said, new players with a background in CPG (as opposed to passionate, but inexperienced, entrepreneurs “who jumped on a trend and ran out of funding”) could change the game.

"You look at new brands like hi! Human Improvement [supplied by Entomo] and they have the right business experience, approach and skillset."

‘Of course we’d like to make money, exit and buy a yacht, but that's not why we got into this’

While money can often run out before patience, he concedes, we should also be realistic when it comes to edible insects in markets such as the US and Europe. “What is a fair timeframe for anything new and novel to gain adoption especially something that so foreign to a Western palate?

“We are mission driven and we started this because we care about people's health and the planet. Of course we’d like to make money, exit and buy a yacht, but that's not why we got into this.”

Chapul founder: 'There is absolutely still mileage in insects as human food'

Chapul founder and edible insect pioneer Pat Crowley – who introduced many Americans to the concept of eating bugs – pulled out of the bar category a few years ago after his co-packer went out of business, and has since focused efforts on raising black soldier flies for pet food, animal feed, and biofertilizer via Chapul Farms.

"There is absolutely still mileage in insects as human food," Crowley told FoodNavigator-USA.

"From a consumer acceptance perspective, it would be enormously helpful for some more established brands (non insect-branded startups) to contribute to the credibility of the idea.

"One piece of feedback from larger brands being resistant to insect-based products, is the lack of available supply chain at scale, so that even if market adoption accelerated, they couldn't fulfill meaningful production based on where the industry is at today. Chicken and egg scenario, with neither the chicken nor the egg wanting to commit to being the first, without the other's participation."

Moving beyond the "superficial, yet widespread 'plants vs. animals' dialogue"

"That is one reason why we are leveraging animal feed and petfood markets at Chapul Farms - because the demand is currently there, at several orders of magnitude in scale greater than edible insect markets. If we build the landscape of the supply chain out around these markets, then it will be that much easier for the human food market participants to engage.

"We support a greater amount of kingdom integration (plant, animal, fungi, bacteria, etc) to foster healthy, vibrant, and biodiverse ecosystems so the move to animal feed for our products isn't as binary as the superficial, yet widespread 'plants vs. animals' dialogue appears to be.

"We actually produce about five times the amount of insect frass as we do insect protein products from our facilities. Insects are midwives to entire galaxies of beneficial microbes that can replace fossil-fuel intensive synthetic fertilizer inputs to plant agriculture, so the end use of the insect protein is almost secondary to the broader positive impacts insect agriculture has on food security, regenerative agriculture, and climate solutions writ large."

*Read the FAO report HERE.

- Check out parts IV and V of our series next week, with Hargol FoodTech in Israel and Gym-N-Eat Crickets in Iowa.

- Edible insects in focus part II: Scale and automation… Aspire Food Group gears up to open world’s largest edible cricket processing facility

- Edible insects in focus, part I: CPG 2nd wave focuses on benefits, not bugs... 'It’s like taking Jell-O and saying, ‘Hey! we've got a bunch of ground up cow bones and sugar. You want some?'