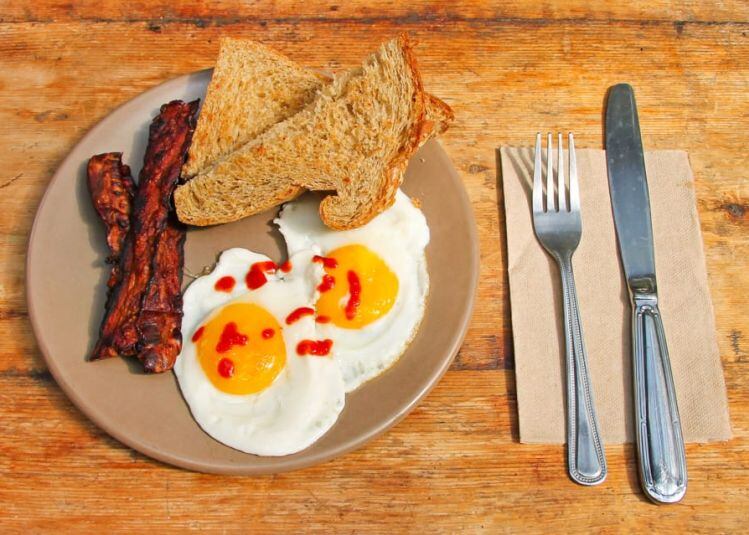

Plant-based meat companies typically rely on extruded soy, wheat, or peas to create processed meat products such as burgers and nuggets, but have been unable to create realistic steaks, bacon, chicken breasts, or other whole cuts, said the team at Atlast Food Co, a spinoff from Ecovative, which has spent years creating materials from mycelium for packaging, textiles, skincare and apparel at its facility in upstate New York.

“We’ve been talking to plant-based meat companies interested in partnering with us over the past six months,” Ecovative director of marketing Andy Bass told FoodNavigator-USA at the Good Food Conference in San Francisco last week.

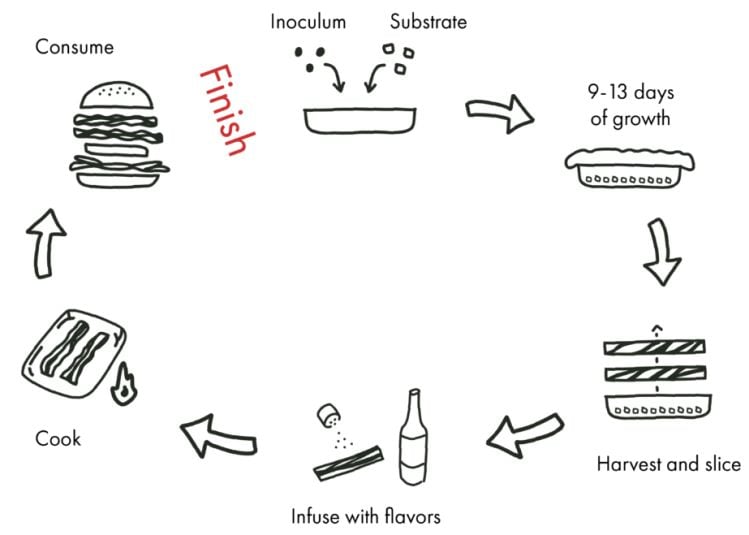

"The easiest way to describe it is that we've created programable mushrooms. We can grow meat-like mushroom tissues in gourmet sheets with various textures and structures at commercial scale in just nine days. Depending on the variety and processing techniques, taste and aroma can range between neutral and the native umami flavor profile of certain gourmet and wild mushrooms.

“The material [which contains protein and fiber] grows in giant slabs and you can then cut and slice it into any shape you want, and infuse it with flavors, fats and other ingredients, or with additional liquid protein such as pea protein or heme."

As to whether firms need to infuse the scaffolding with additional protein, he said, "This depends on the variety and processing technique. We are currently exploring the native amino acid profiles which can be produced as well as options ranging from targeted additions to macro-level protein source additions. Atlast Food Scaffolding is an ingredient component which we imagine may form the basis for a number of center of plate products in the future, each of which may rely on different downstream formulations depending on the product."

Cell-based meat

He added: “We’ve also been doing some beta testing with cell-based meat companies [who are looking to seed animal cells onto edible scaffolding that is robust enough to hold its structure but porous enough to be can be infused with growth media]. By modulating the conditions we can also tune the porosity of the scaffolding.”

Regulatory status

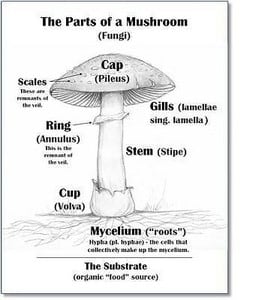

Asked about the regulatory status of the scaffolding, he noted that Ecovative is using existing edible mushroom strains which meet GRAS determination when grown in conventional mushroom farms, but added: "We are still in the process of evaluating regulatory strategy, including the question of whether an existing GRAS determination for the mushroom cap will be applicable to our process [which uses the roots].

"The nutritional, chemical composition, and other elements are similar between different morphologies (structure) of mycelium tissue."

As for how the mycelium might be labeled on an ingredients list in the US, he said, "We are still evaluating ingredient label options."

At Ecovative, our mission is creating next generation materials through mycelium biofabrication. We do this by influencing how mycelium grows and the micron level structures it forms.

We can also make novel snacks that are high in protein and fiber

By spinning off Atlast into a separate entity, Ecovative is aiming to attract investors and food specialists to help commercialize its technology, said Bass, who told conference delegates that whole cuts were the ‘Holy Grail’ of meat, accounting for the vast majority of sales in the [regular meat] category.

"We're here today seeking strategic institutional investors for Atlas Food Co."

Ecovative, which has a suite of patents around the production of its mycelium-based materials, grows the mycelium on [food grade] “plant-based waste” but can alter its nutritional composition by adding additional nutrients to the growth medium, said Bass.

“We can also make novel snacks that are high in protein and fiber with a cheesy puffball-type texture, so there has been a lot of interest in those too, as well as things like crispy pizza dough.”

Asked about patent protection, he explained: "Ecovative has filed over 40 patents in 31 countries. As it relates to our work in food, we have filed patents around the production of this tissue type, which is universal to multiple strains of my mycelium, as well as specific applications in food and specific process steps one might use to create various types of plant and cell based meats using our scaffolding."

Ecovative’s biofabrication processes enable it to tune the porosity, texture, strength, resilience, and fiber orientation of mycelium based on the desired performance characteristics of the material it is producing.

‘We have been quietly working on prototypes of new food products’

In a blog post on the company’s website, Ecovative CEO Eben Bayer explained that the company started created bacon samples in the company’s kitchens last fall using mycelium strains developed for its textiles, but then identified new strains more suitable for food applications as they were a little “too tough.”

By the summer of 2019, he said, “it became clear we would want to put together a focused team around this opportunity,” given that, “By far, the most valuable parts of an animal (82% by value), and the biggest impact in terms of changing consumption (75% by volume) are whole cuts of meat.”

He added: “We have been quietly working on prototypes of new food products leveraging Ecovative’s mycelium foundry and have been extremely encouraged by the results and feedback from trusted partners and the handful of global brands we’ve shared them with.”