“We’ve designed our process to fit into existing white button mushroom farms with beds 100 feet long and 10 or 20 feet wide,” said Eben Bayer, CEO at Atlast, which has just launched MyBacon, the first retail product under the MyEats brand, at the Honest Weight Food Co-op in Albany, but is primarily focused on building a b2b business.

“So you’ll get 100-foot long slabs of mycelium meat, and we’ll go in and slice it into pork belly-like sections that can go into a high-speed meat slicer, and we’ve tested that, and so you can get to economics that are very competitive with pork belly,” Bayer told FoodNavigator-USA.

He added: “We’ve just completed our ‘baby’ 100,000lb deployment and now we’re looking at locations in New York and Pennsylvania [for a larger site]; we’ll make a final site determination early next year.

“We’re working with one of the largest mushroom farm builders in the world based in The Netherlands, and the equipment is being shipped in in trailers and we’ll assemble it on site. In a pinch you could grow regular mushrooms in it, and it should be that way, as the next step after we’ve built this, is going to major mushroom growers in the US and saying, would you like to produce the next 25 million pounds?”

‘We’ve entered into multiple b2b partnerships’

So what kind of interest has Atlast had from food companies about using its meaty materials, which can be grown at around room temperature? “We’ve entered into multiple b2b partnerships and we’ve sold all of our planned capacity through 2023,” said Bayer.

“There are a lot of plant-based companies with great brands out there [selling burgers, sausages, nuggets etc] but it seems to me that no one has a great solution for whole cuts.

“So there’s an opportunity to scale massively and provide this as an ingredient to b2b partners and let them brand it and take it to market as a bacon, or as a jerky, chicken or fish, and so on; we didn’t want to fight over shelf space and trade spend, as we’re a b2b business fundamentally.”

Why launch a consumer product?

That said, Bayer wanted to get the product in front of consumers in the real world (ie. will they actually part with cash to buy it rather than telling researchers they would probably buy it?), albeit on a small scale, in order to gain learnings, validate the product and the positioning, he said.

“We’ve fed this bacon to a lot of people this year and done home use testing, but until people are buying your product every week in retail and telling you they love it, you don’t believe it.

“Now people are buying it and loving it, so we are getting some market validation,” added Bayer, who raised $7m in a seed funding round in May for Atlast, a spinoff from Ecovative Design (which he co-founded), which uses mycelium in packaging, textiles, skincare and apparel.

The production process

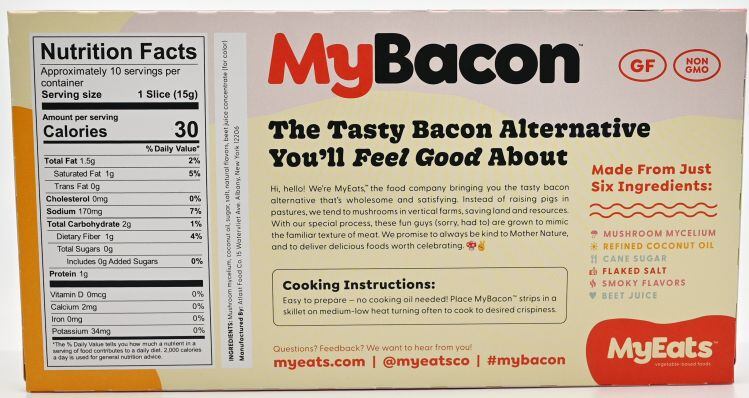

While most meatless bacon uses soy and/or wheat protein (newcomer Hooray Foods is unusual in that it uses coconut oil, rice flour, and tapioca starch), Atlast Food Co grows mushroom mycelium in trays via solid state fermentation to create ‘meaty’ fiber- and protein-rich slabs in a matter of days that can be cut and sliced into multiple shapes.

Atlast grows the mycelium on food grade “plant-based waste” but can alter its nutritional composition and flavor both by adding additional nutrients to the growth medium or infusing it with additional protein or other ingredients post production, said Bayer.

“We’re not trying to be the lowest cost most nutritionally complete protein with the perfect PDCAAS score, we’re trying to be the highest performance structured protein on the market, but it’s a really healthy product and sufficiently high in protein [on its own] to serve as a meat substitute.”

'A compelling meat substitute'

Texture can also be adjusted through altering the environmental conditions as the mycelium grows, he said, noting that Atlast’s biofabrication processes enable it to tune the porosity, texture, strength, resilience, and fiber orientation of mycelium based on the desired performance characteristics of the material it is producing.

“You can grow products that are incredibly soft or as hard as wood; it’s actually growing over a 10-day period in layers that are only 30 microns thick, which is close to the fiber size of muscle meat, and we can influence how those layers form. You can grow parts that are dense and parts that are less dense that preferentially uptake fat, which makes it such a compelling meat substitute.”

Asked about IP, parent company Ecovative has filed patents around its process in general and specific applications, but has also built IP around things like creating tiny perforations in the foam-like material that influence how it fries, he revealed.

Atlast has a “lifetime, non-revokable exclusive license to everything Ecovative ever created or will create in the field of human food."

Regulatory questions

Atlast is using existing edible mushroom strains which are GRAS (generally recognized as safe) when grown in conventional mushroom farms (that are focused on mushroom caps rather than mycelium; their filamentous-like roots).

And while there might not be a history of use of eating the mycelium it is growing, Atlast’s products are “substantially similar to gourmet mushrooms on a molecular and structural basis,” so do not present novel food safety concerns, he claimed.

*All pictures courtesy of Atlast Food Co