The round - supported by Mirae Asset Global Investments, GIC, Viking Global Investors, Disruptive, Andreessen Horowitz, Tenere Capital, Sweetwater Private Equity, Tao Capital Partners, K3 Ventures, David Barber of Almanac Insights, Michael Ovitz of Creative Artists Agency, Anne Wojcicki of 23andMe, Susan Wojcicki of YouTube, and Katy Perry - will help Apeel expand its team and build its international footprint.

Apeel – which already works in eight countries operating 30 supply networks distributing Apeel-protected produce to 40 retail partners and tens of thousands of stores – plans to activate at least 10 additional supply networks by the end of the year, said founder and CEO Dr James Rogers, who founded the business in 2012 with a grant from the Bill and Melinda Gates Foundation.

Hyperspectral imaging technology

It will also use the latest cash injection to integrate hyperspectral imaging technology developed by ImpactVision (a startup acquired by Apeel in May) to assess ripeness, nutritional content, and other indicators of quality and shelf life at future deployments to help partners further food waste.

While experienced growers might have pretty good insight into how their produce ripens/matures over time in the aggregate, there can be meaningful differences between, say two avocados harvested from the same farm – or even from the same tree – that cannot be determined though a visual inspection (by humans), Rogers told FoodNavigator-USA.

“Avocado trees are not factories [producing uniform products], so even whether a fruit grew on the outside of the tree or on the inside of the tree makes a difference, what spot of the field it came from and so on.”

By mounting ImpactVision technology above a conveyor belt and capturing images of avocados in real-time as they pass below, packers could use objective criteria invisible to the human eye to divert pieces of fruit into different streams, for example, observed Rogers, who said Apeel may use the latest funds for more acquisitions expand its data capabilities.

“I have an avocado in my left hand that is indistinguishable from the one in my right hand. One will be made into guacamole, the other will go on a boat to North America. Which one should I send? With the implementation of this technology, it allows us now to differentiate between those two.

“Now you can sort not just based on size and color, but a variety of additional dimensions.”

Colorless, odorless, tasteless and undetectable on produce

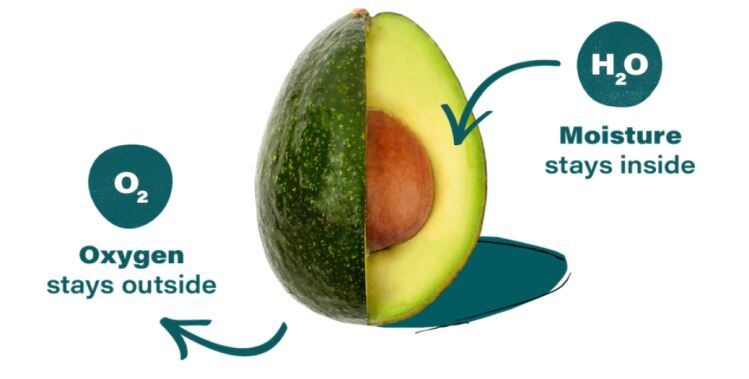

Supplied as a powder that can be mixed with water and sprayed or brushed onto produce, Apeel's invisible skin is made from plant extracts (primarily lipids from agricultural by-products such as grape seeds) which self-assemble into structures - an edible ‘skin’ of consistent thickness - that allow Apeel to independently modulate the rate of oxygen and carbon dioxide transmission to create an optimized microclimate.

The lipid content does not, however, make Apeel waxy or greasy: it’s colorless, odorless, tasteless and undetectable on produce (no sticky or waxy residue), said Rogers, who said the business case for using Apeel is compelling at every step of the supply chain.

In the case of long English cucumbers, for example, applying Apeel means firms can ditch the plastic shrink-wrap; while for asparagus, the extra shelf-life means it can travel by sea instead of air, without the use of controlled atmosphere, reducing costs.

Avocados treated with Apeel have up to 50% longer shelf life, slashing retailers’ shrink and giving consumers more time to enjoy them at peak ripeness; while for limes, Apeel can triple shelf life, giving growers and distributors access to new markets.

COVID-19 supply chain disruptions

And while extending the shelf-life of produce provides commercial benefits at the best of times, the ROI during the pandemic has been particularly compelling, claimed Rogers, with supply chain disruptions and changing consumer habits (surges in demand at grocery stores in the early weeks of the pandemic coupled with larger basket sizes and fewer trips) putting significant strain on supply chains.

Retailers - who are constantly trying to find the right balance between having sufficient inventory on hand to meet consumer needs and trying to keep shrink (food waste) as low as possible – benefit from every extra day of shelf-life Apeel can deliver, he added.

“That's a really difficult equation to balance, especially if you've been doing it off of historical information. What we’re providing our customers with is more time.”

Put in simpler terms, applying Apeel could make the difference between a delayed shipment rotting, and fruit ending up on supermarket shelves, he said, while there can also be cost savings where, for example, produce was historically put into a cold room in a given location, but with Apeel, could be stored at ambient temperatures, given the additional protection yielded by the invisible skin.

Retailers believe that the future is fresh

To date, Apeel has commercialized its technology for avocados, organic apples, citrus fruits, and cucumbers, but is also working on a variety of other applications for its invisible skin, which can work on a broad range of products including cut fruits and vegetables, and can be made from a variety of plant-based feedstocks, although the more homogenous the source material, the better, said Rogers.

“Retailers believe that the future is fresh, and that the center of the store is going to move to online sales and shoppers are going to be looking for them to curate experiences in their stores. And they think that that experience is being driven by fresh foods. And so we're really focused on delivering the solution for them in fresh.”