The problem, says Bhuyan - who is developing invisible, food-safe, edible biological tags that can be sprayed onto anything from grains to leafy greens at source and ‘read’ like a regular barcode with PCR or other tests – is that many foods, from fresh produce to cocoa beans, are sourced from thousands of individual farms or growers and combined before they are packaged and labeled.

The paperwork might say they are responsibly sourced, organic, grown without child labor, or originated from a farm in outer Mongolia, but there’s often no real way of validating this from the actual product itself.

And while record-keeping has improved as firms seek to comply with the Food Safety Modernization Act (FSMA), it can still take weeks and months to work out that the lettuce responsible for an E. Coli outbreak came from Joe Bloggs’ farm in California, while trying to determine precisely where palm oil, coffee or cocoa beans came from in many cases is well-nigh impossible if the paperwork can't be trusted.

Bloggs, as the responsible party for our hypothetical outbreak above, is covered by his insurance, says Bhuyan, but his neighbor – whose products were also destroyed - may be “collateral damage.”

“So Walmart, or whoever, will destroy all of the lettuce because it might take up to two months before they work out whose actual outbreak it is. The person who's responsible is likely covered by an insurance policy, but other people whose product has been destroyed, it's not their recall so they may be collateral damage.”

An economic, as well as a safety issue…

With bio barcodes, you may be able to slash that investigation “from literally several weeks, to maybe a day, or even an hour,” claims Bhuyan, who is hoping to start applying his bio barcodes to products “towards the end of next year.”

“We’ve got a massive problem in recalls. You’ve got a $50bn+ crop insurance market that can’t keep the record straight, and you not only have a safety issue, but also the issue of how do you determine who's liable?”

With leafy greens, he said, “You could 10,000 farms coming into a handful of processing plants, and nothing really is truly traceable until after it's in a bag and it has a barcode, so what we've found is, all the real complexities come in the first and second mile.”

In a 2018 E. coli outbreak linked to Romaine lettuce, for example, the CDC ultimately traced the incident back to a farm in Santa Barbara county, announcing the findings of its investigation in early 2019.

In the meantime, however it had “advised the public [in November 2018] not to consume romaine lettuce and to destroy any romaine lettuce in their homes.”

It also issued a request “that all romaine lettuce on the market, including in restaurants and other commercial establishments, should be withdrawn and destroyed,” as a blanket “market withdrawal was the fastest way to remove potentially contaminated product.”

Not pretty, says Bhuyan.

Non-safety-related recalls…

Non-safety-related recalls, meanwhile, are also “becoming a thing,” he claimed. “Let's say you've got a coffee chain that imports 10,000 pounds of coffee beans, but it's later revealed some beans were harvested using child labor. Now there’s a recall, but how do you verify exactly where they’ve come from?”

In other cases, being able to validate claims made by suppliers rather than relying on a paper trail could also be a valuable application for bio-barcodes, he said, citing sustainable palm oil – which comes at a hefty premium - as an example.

If you’re buying a million tons of certified sustainable palm oil for your lipstick brand, you have no idea from the oil itself if you’re getting what you’re paying for, he observes.

How does it work?

So how does Aanika Biosciences’ technology work, is it safe, and does it have to be labeled?

According to a patent application filed last year, the company “leverages the durability, safety, and microscopic size of microorganisms…to carry one or more biological barcodes that serve as a unique identifier to a physical article that is associated with the biological barcode.”

The invention “preserves a biological barcode through rigorous environmental conditions of certain supply chains [the bio-barcodes are not degraded by heat, light, humidity, harsh processing etc]” that can be read “via multiple analytical methodologies, thus, allowing for a simpler, faster, and cost effective solution for tracking physical articles through a supply chain.”

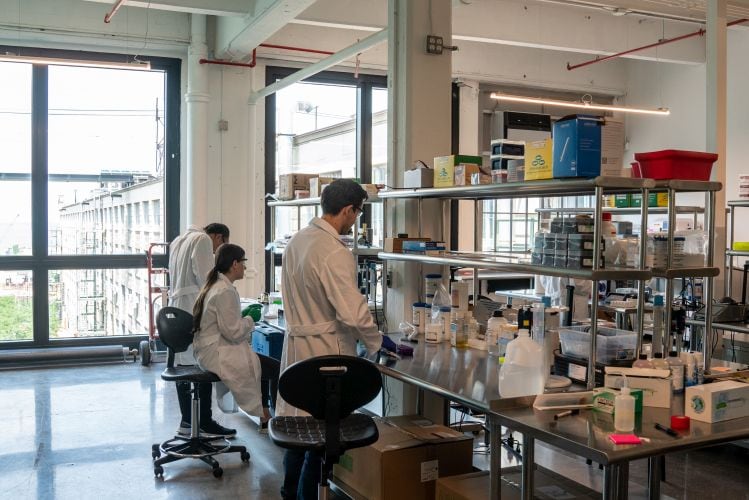

The technology could use various microbes (yeast, algae, viruses etc), but in its first iteration, Bhuyan and co-founder Dr Ellen Jorgensen, a molecular biologist, are using inactivated bacterial spores that are genetically modified to carry the nucleic acid biological barcode in the genome or displayed on the surface, explained Bhuyan, who founded the Brooklyn-based company (formerly Carverr, Inc) in late 2017.

“It's in spore form and it’s incredibly robust and incredibly adhesive to organic matter, and the tags can contain an endless variety of digitally encoded information from a lot number to a distributor number to a batch number, water mark of authenticity, a patent number, a farm, a particular harvest from that farm – whatever you want.”

While a small number of companies has explored the biological barcode concept before, “The biggest difference between them and us, is that they “shied away from the GMO aspect of things,” claimed Bhuyan.

“They use what’s called ‘naked DNA,’ so strands of synthetic DNA, but the problem is that when you’re dealing with UV light, heat, humidity, storage conditions, processing, it doesn't last, whereas we can go the whole route of a supply chain.”

GRAS determination

From a regulatory perspective, Aanika Biosciences is currently putting the finishing touches on a GRAS (Generally Recognized as Safe] determination, he said: “We’ve had ongoing conversations with regulators who understand that what we're doing is incredibly safe.”

So what gives him this level of confidence, and what happens to the spores when you ingest them?

According to Bhuyan, “They just pass through you. You're already digesting hundreds of millions of microbes and spores every day, this is nothing new. They are not populating your gut. It’s not germinating; it’s inactivated, we've removed the genes necessary for it to come out of that dormant state.”

This is in contrast to something like Ganeden's probiotic spore-forming bacteria BC30, he says, which is a hardy resilient organism that survives the stomach acid, and then starts germinating when it reaches the intestines in order to confer its health benefits.

Labeling: The GMO factor?

So what about labeling? Given that the whole point of AanikaBio's technology is that it contains ‘detectible’ modified DNA, which will trigger ‘bioengineered’ food labels in the US from January 2022, does this mean that foods featuring it will have to be labeled as ‘bioengineered’?

According to one regulatory expert contacted by FoodNavigator-USA, it could technically be considered as an incidental additive (and therefore exempt from labeling) as it’s not an ‘ingredient’ per se, and arguably performs no function in the product (aside from serving as a unique identifier).

The source added: “The 5% threshold [for inadvertent contamination] in the National Bioengineered Food Disclosure Standard definitely would not apply because it is an intentional component. If the ingredient statement of the food package is not going to include the bio-barcode spores, because they are being considered a processing aide or incidental additive, however, then the spores would not trigger the bioengineered food disclosure.”

But he added: “The question I would have though is whether it is appropriate to consider the bio-barcode an incidental additive. The short definition is not having a technical or functional effect in the food, but I expect that requires consideration of how, and by whom, the bio-barcodes would be used.”

Bhuyan: 'We are GMO and we are not shying away from it'

Bhuyan, meanwhile, says he’s not losing a great deal of sleep over this given that he envisages firms will want to be proactive about their use of his technology to reassure consumers and supply chain partners: "We want to turn our product into a badge of authenticity. We are GMO and we are not shying away from it.

“I think attitudes towards GMOs are beginning to change thanks to companies like Impossible Foods [which uses protein from genetically engineered soy as its #1 ingredient, and soy leghemoglobin - 'heme' - from a genetically engineered microbe as its flagship flavor and color ingredient].

"Leonardo DiCaprio just joined the Sustainability & Health Advisory Council at Perfect Day [which is genetically engineering microbes to produce dairy proteins without animals with a significantly lower environmental footprint], and he is like Mr Environment.”

The business case

So when it comes to the return on investment, what’s the attraction of bio-barcodes for potential customers, and what’s the most efficient strategy when it comes to commercialization?

“We're talking to the real gatekeepers in the produce industry and insurance companies, but also partnering with organizations like GS1, which maintains all the barcodes in the western hemisphere,” said Bhuyan.

“Our goal is not to persuade 10 million individual farmers to use our technology, but to sell to the critical members of the supply chain that will sort of mandate it.”

It’s a cost, he said, but recalls can cost millions, he points out, so “a marginal increase to your cost of goods sold, it's like an insurance policy, a protection on the ‘what if?’ cases.

“But to me, it’s also about the fact we're entering the world of branded commodities, so for example, I love what Apeel Sciences is doing [with its invisible edible skin which extends the shelf life of fresh produce], by branding the avocados [that feature the edible skin] as ‘Apeel’ avocados.”

He added: “I can't say too much at this stage, but we've partnered with some of the biggest players in the biotech industry and created some additional functions, so essentially, that can not only tag something, but let's say fight off a pathogen, because the biggest follow up question we get is, if we're going to spray this on something, is there something else you can provide? And the answer is yes, as our tags are an incredible vehicle for other functions.”