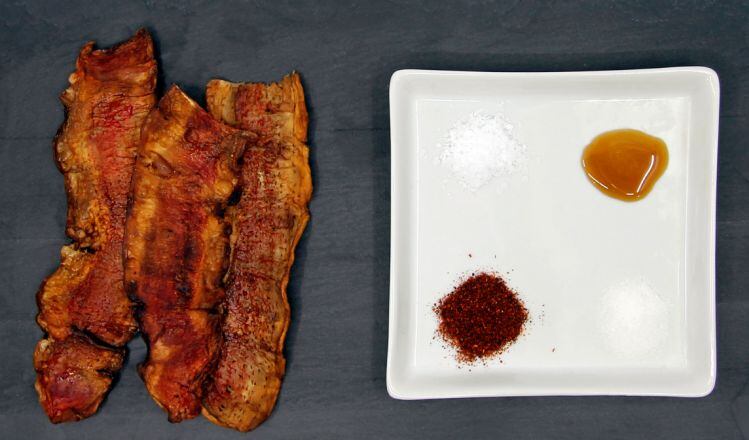

A spinoff from Ecovative, which uses mycelium in packaging, textiles, skincare and apparel, Atlast uses the filament-like mushroom material to create ‘meaty’ textured edible 3D structures, including its plant-based MyBacon strips.

When MyBacon launched in late 2020 it create a splash as one of the first-to-market alternatives to “whole-cut” meat, like steak or chicken breast, which many see as the ‘holy grail’ of plant-based meat in a market dominated so far by grounds, burgers and nuggets typically made from extruded soy, wheat or peas.

But since launching, MyBacon, produced under the brand MyEats, has only been available for purchase at Honest Weight Food Co-op in Albany, NY, near Atlast’s headquarters. Others hoping to try the product have had to rely on special events, including one-day-only collaborations with local restaurants.

Soon, however, Atlast expects to make MyBacon strips more widely available thanks in part to its new partnership with Whitecrest Mushrooms, which will pair its growing expertise with Ecovative’s AirMycelium technology to fine-tune environmental factors that influence mycelium’s shape and density.

Through this partnership, Whitecrest Mushrooms will build a dedicated farm that will produce nearly 3 million pounds of MyBacon mycelium on less than one acre of land, the companies announced Jan. 11.

The deal follows a successful trail with Whitecrest Mushroom that demonstrates Ecovative’s AirMycelium technology can be applied to existing mushroom farms, suggesting other arrangements could be made in the future – although Whitecrest has an option to increase production in 2023.

The news follows that of a $40m series A fundraise led by Viking Global Investors announced last April which will allow Atlast to build an 80,000 square foot vertical mycelium production facility next to its New York-based headquarters that will become operational this year and focus on B2B customers.

As the company scales, it won’t necessarily be restricted to creating plant-based meat, as the nutritional composition and flavor of the slabs of mushroom mycelium can be altered by adding different nutrients to the growth medium, the company’s director of marketing Andy Bass previously told FoodNavigator-USA. The slabs can then be cut and sliced into multiple shapes.

Given the versatility of Atlast’s innovation and the growing demand for whole cut poultry, in particular, the company’s decision to feature ‘bacon’ as its hero product was based on the limited competition in the plant-based bacon segment, which currently is valued at an estimated $30-35m of a $9bn market.

protein-rich slabs of mushroom mycelium can be cut and sliced into multiple shapes and ostensibly flavored to taste like different poultry and meat.