nth Bio – established in Salt Lake City, Utah earlier this year – will offer Onego Bio strain engineering, bioprocess development, regulatory support, and scale up process services as Onego Bio attempts to commercialize animal-free ovalbumin (brand name ‘Bioalbumen’), the most abundant egg white protein, using precision fermentation.

As with Perfect Day's animal-free whey protein, Onego Bio's animal-free egg proteins - which are produced by genetically engineered microbes feeding on sugars in a fermentation tank - are designed to offer the nutritional and functional benefits of animal proteins (the proteins are bio-identical to those found in eggs), without the environmental, ethical and safety-related concerns associated with industrialized egg production.

Ovalbumin... the most prevalent protein in egg white

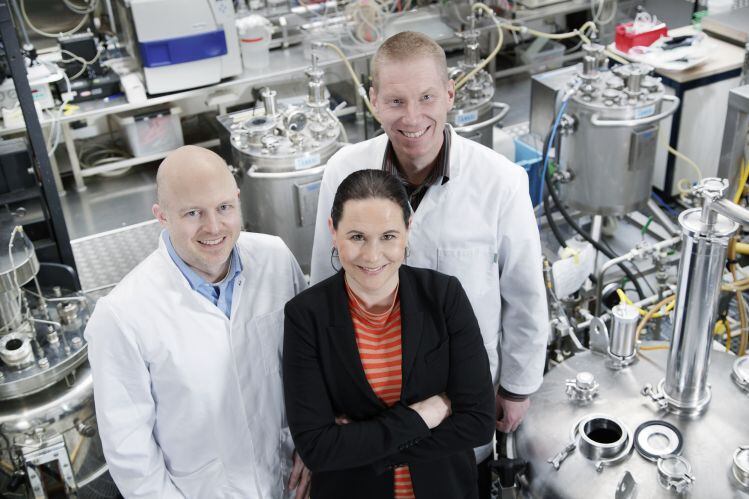

A startup spun out of VTT Technical Research Centre of Finland and founded by Maija Itkonen (CEO), Christopher Landowski (CTO) and Jussi Joensuu (COO), Onego Bio is not the first player to get into the animal-free egg protein space, an area pioneered by Bay area startup, The EVERY Co, which uses yeast cells to make a variety of egg proteins.

However, Onego Bio deploys a different micro-organism (a strain of Trichoderma fungi) to make its egg proteins.

Described by Perfect Day co-founder and CEO Ryan Pandya as “a serious new player in the field,” Onego Bio aims to target the US bakery and confectionery market in the first instance, but is also eyeing the protein supplements/fitness market and considering a move into the consumer market with its own branded products for baking and cooking.

nth Bio: From strain to shelf

So why is Perfect Day getting into the enterprise biology space, and what kinds of support can nth Bio provide to aspiring startups in the precision fermentation arena?

Perfect Day has already produced more animal-free whey protein in the first half of this year than it did in all of 2021, with the capacity to produce “thousands of metric tons” starting next year through four commercial-scale facilities on three continents, while many startups in the space are still trying to get off the ground, global head, commercial, Ravi Jhala told FoodNavigator-USA.

“When we speak with a customer or a partner, they are often in awe over what we have been able to accomplish in terms of being able to operate at a larger scale. We have an incredible team trying to create solutions from strain to shelf, and that's the kind of service that we want to offer [through nth Bio], from strain design to screening, to fermentation, to downstream process development, to piloting, to scale up."

There are already experts in all of these individual verticals, he acknowledged, "but there is no one that really connects them all, and if all the new startups in this space have to reinvent the wheel every time, we simply would not have the type of impact that Perfect Day is trying to create.”

'If all the new startups in this space have to reinvent the wheel every time...'

As for the business model at nth Bio, which is also talking "at least three to four other businesses that are in very late stage of partnership agreements," he said, it could be pretty “transactional in nature depending upon what they need from just a pure service standpoint, but it could also be a more strategic partnership wherein we are working hand in hand with a partner to bring a finished product to the shelf.”

The nth Bio facility in Salt Lake City, Utah is "currently in the construction and commissioning phase" and "expected to go live in the third quarter of 2023," said Jhala, who said it would have dedicated staff as well as key executives from Perfect Day that are wearing two hats.

"The primary focus of the facility is going to be bioprocess development, piloting and scale up plus other resources and capabilities around strain design and screening.”

He added: “We started our journey in the food protein space, but we can extend to other things like personal care, biologics, materials, and we can support [companies working with] yeast, fungi, and bacteria [as host microorganisms].”

'Animal-free' proteins

There is no formal definition of ‘animal-free’ protein – a term being tested by some startups in the space – but it typically refers to products made with ‘real’ animal proteins (whey, casein, collagen, egg ovalbumin, myoglobin) that are produced without animals, either via genetically engineered microbes or genetically engineered crops such as soybeans or peas.

Using synthetic biology, firms in this space effectively 'program' plants or single celled organisms such as fungi and yeast to express animal proteins after feeding on sugars in fermentation tanks.

The final proteins are already familiar to the food industry (in its GRAS determination for its animal-free whey protein, which is expressed by a genetically engineered strain of filamentous fungus, for example, Perfect Day notes that it is "identical to commercially available bovine-produced β-lactoglobulin”).

While it has its detractors, using precision fermentation to make dairy and egg proteins without animals, argue proponents, offers the best of both worlds: more sustainable and ethical products that don’t involve industrialized animal agriculture, but still deliver the nutrition and functionality of animal proteins.

While plant-based dairy and egg alternatives have improved significantly in recent years, they argue, animal proteins can deliver certain technical or functional properties that can be hard to replicate using plant proteins, from the melt and stretch of casein proteins in cheeses such as mozzarella and Cheddar, or the aeration, binding, coagulation, emulsification, foaming and whipping properties of egg whites.

nth Bio: from strain to shelf

nth Bio can offer assistance with:

Micro-organism strain development: Running strain improvement studies by improvising and optimizing microbial fermentation.

Tools and IP licensing: Accessing manufacturing equipment to maximize efficiency and optimize affordability while protecting IP and navigating technology licensing.

Pilot scale fermentation services (1-2000L): Scaling upstream and downstream milestones, from proof of concept and process optimization to product specifications and requirements.

Downstream process development: Developing and implementing processes to isolate, recover and purify product.

Regulatory approval strategy: "One of the key things that a lot of our collaborators and partners are looking for is regulatory support, as sometimes navigating those conversations can be pretty challenging, so we are investing some substantial resources to help our partners in this respect," said Jhala.

Image credit: Perfect Day

Founded in 2014, Berkeley-based Perfect Day supplies startups, emerging brands and multinational CPG cos (General Mills, Mars, Nestlé) with animal-free beta-lactoglobulin, the primary protein in whey, as a b2b ingredients supplier, with other products in the pipeline including alpha-lactalbumin (another whey protein) and casein proteins.

It has also developed its own consumer brands via The Urgent company, which makes a variety of CPG brands deploying animal-free whey protein including Brave Robot and Coolhaus (ice cream), Modern Kitchen (cream cheese) and California Performance Co (protein powders).