Busy labs only get busier as demands increase and funding grows tighter. Automation is an obvious solution on paper, but it usually comes with a hefty start-up cost. What if it doesn’t work? What if the employees do not adopt the new technology? What if the time spent preparing the equipment ate up all of the time saved?

Jolanda Nortjé, Laboratory Manager of The Southern African Grain Laboratory (SAGL), wrestled with these questions. Working with grains meant a lot of thermogravimetric analyses, but the standard oven drying methods her lab used were incredibly time-consuming. Depending on the flour matrix, oven times could range from 1 hour to 17 hours. Whole grains could take a full 72 hours. She wanted—needed—a better way.

When Nortjé heard a lab was needed for a study comparing primary moisture loss-on-drying determination between standard methods and an automated version using LECO’s TGM800, she realized she had a chance to test automation in her lab and agreed to participate. The TGM800 was brought in, and Norjé began the study.

Three types of grains were analyzed by SAGL in this comparison: whole sunflower seeds, maize meal, and flour (whole wheat and white wheat). These samples were production samples currently being analyzed by SAGL, so the results would demonstrate how applicable the TGM800 was to the actual work the laboratory was doing. The TGM800 and standard oven drying methods were performed on the same day for each type of grain to eliminate any variation from moisture loss during storage.

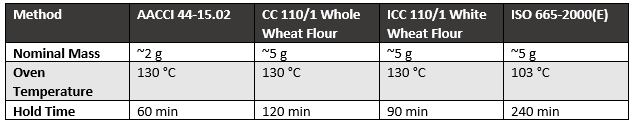

For the oven-drying methods, AACCI 44-15.02 Moisture in Maize Meal, ICC 110/1 Moisture in Whole Wheat Flour (2 hours), ICC 110/1 Moisture in White Wheat Flour (1.5 hours), and ISO665-2000(E) Moisture in Whole Sunflower Seeds were followed, as indicated in Table 1. The TGM methods used the settings found in Table 2.

Table 1: Manual Oven Loss-on-Drying Method Parameters

Table 2: TGM800 Methods

The SAGL found that the differences in average moisture between manual and automated methods using the TGM800 were on average 0.06%. The TGM800 was providing the SAGL with the same results as the oven drying methods.

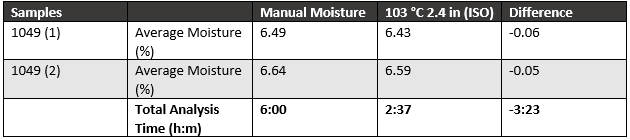

However, the difference came with the analysis time. For the whole sunflower seeds alone, the oven drying method took 6 hours to complete.

In the TGM800, the laboratory had the results in 2 hours and 37 minutes. This was a time savings of 3 hours and 23 minutes for just two samples. The sunflower seeds' results are displayed in Table 3.

Table 3: Sunflower Results

After the comparison concluded, Nortjé knew the initial cost of automation was worth the time-savings. Between this study and her previous experience with LECO, she is budgeting to purchase the TGM800 for her lab with confidence in her future productivity. Busy labs only get busier, but the SAGL will now be able to handle the load.

Download our poster to see the full results of the experiment.