The products - made from cells grown outside an animal in a plant-based growth medium - will debut in a yet-to-be-announced overseas market owing to the lack of regulatory clarity over selling cell-based meat in the US right now, said Tetrick, who was speaking to FoodNavigator-USA at the Good Food Institute’s (GFI’s) Good Food Conference at UC Berkeley last week.

Asked when JUST might be in a position to produce enough cell-based meat for say, 500+ restaurants or stores at an affordable price, he said: “We’re looking at some time in the next two to three years for that kind of quantity. We’ll start at high end restaurants and then move to retail.”

Structured products ‘much further out’

As for the timeline for developing more complex structured products that may require some kind of edible scaffolding or other technology to produce thicker tissue containing fat, muscle, and connective tissue in the same ratios and formations as a beef steak or chicken breast, he said this was “much further out,” but added:

“One thing people miss about this whole cultured meat thing is that it’s not just a question of a steak or not, or even 100% meat products or not. There could be blended products with 50% plant and 50% clean meat. It’s not a steak or nothing, or something that has to be everywhere straightway."

Speaking after Memphis Meats CEO Uma Valeti MD told delegates at the conference that it might be 10-15 years before cell-based meat captured a significant chunk of the market, Tetrick said: "There’s no example of any breakthrough technology that’s ever just been everywhere all at once. It's a process."

“If my Dad can go to Walmart and buy cheap cod for $2.99 or [cell-based] Bluefin tuna for $2.49, then he might pick the tuna.

"If you can figure out how to get the cost down and the quality is better, it doesn’t matter if they [consumers] care about animal welfare, if they understand anything about the GFI, or if they believe in the science of climate change, or if they are a Trump voter… that’s when the switch [from conventionally produced meat to cell-based meat] will occur…”

Josh Tetrick, founder and CEO, JUST

Intellectual property

So how important is having your own intellectual property (IP) in the cell-based meat space at this stage of the game, and will third party players in related disciplines play a significant role in the development of growth media, cell lines, bioreactors, scaffolding and other components required to scale the technology?

Tetrick, who has variously been described as “one of the best capital raisers in the business,” and someone heading a “food company masquerading as a tech company,” added:

“Any time one is raising capital, IP has some relevance, whether you’re making a phone or clean meat, so the first part of our IP relates to how we screen plants, which could potentially feed into identifying components in the growth media that are critical to removing one of the limiting steps to make cell-based meat happen, and we have the first ever patent to utilize machine learning for that kind of approach in the food industry.

“Second, we have trade secrets around how we process these plants. And third, we have [recently acquired] a set of patents [click HERE and HERE] around the process of production for clean meat that we own, that are probably the broadest patents in the field.

“Our perspective is that IP is important; we’re open to the idea of enabling others with our IP too, we’re not trying to hoard everything, and every day we continue to develop more IP around how we isolate cells, the process of upscaling and how we bring the products together.”

Asked whether JUST’s plant screening work had already identified more cost effective growth factors [the components in cell culture media that signal the cells to differentiate into specific cell types etc] he would not provide details, but said, “We’ve gained a lot of experience in understanding which plants work and which won’t work.”

While the optimum growth media for cultivating, say, blue fin tuna cells vs cow cells may be very different, and 100 different cell types would require 100 different media recipes, JUST will focus on a handful of the most widely consumed animals, he said: “Four key species make up north of 50% of the world’s meat production: chicken, lamb, cow, and pig, so we’re focusing on the big ones.”

The JUST business model

As for the JUST business model, this involves developing branded products in-house and potential licensing deals, added Tetrick, who has led his seven-year old company through some choppy waters over the past 18 months amid damaging reports of boardroom power struggles and disputes over the strategic direction of the business, although he insists that “the facts are radically different from what is reported.”

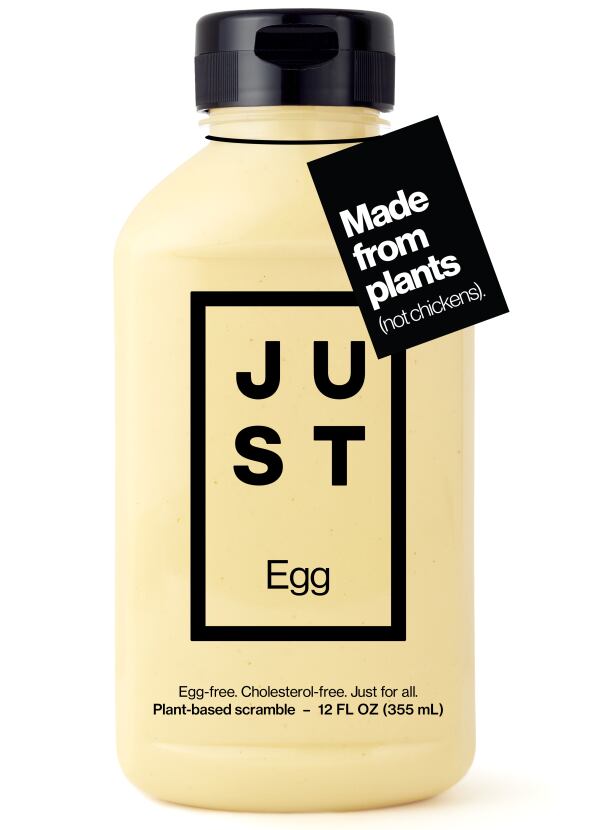

If you were to boil down the JUST strategy to two things, he said: “it’s to find tools, whether it’s muscle cells, fat cells or mung bean protein [used for egg replacement], use them to make meaningfully different products with the Just brand on them such as Just Egg or Just Chicken, and then identify companies that get it, that want to go fast, that want to manufacture, and want to distribute, and license those tools to them.”

The team: We have a phenomenal group of scientists across a wide range of disciplines

Asked whether the departures of Eitan Fischer and David Bowman (who formed cell-based meat start-up Mission Barns earlier this year) and other staff previously described as being integral to the project, including former VP process R&D Jason Ryder and senior scientist Aparna Subramanian, had delayed progress, Tetrick said:

“We have 50 or so people on our R&D team, many of whom are working on clean meat, much of our product development team, much of our process team… And the discovery team is embedded with the clean meat team.

“We have a phenomenal group of scientists across a wide range of disciplines, including our chief technology officer Peter Licari, a phenomenal process engineer [a specialist in microbial fermentation previously at microalgae firm Terravia]. This requires computational biology, process engineering, food science, culinary, and other disciplines.”

JUST Egg: ‘To get the unit economics to below the cost of production of a chicken egg we need to sell the mung bean starch for a decent amount’

Quizzed about the mung-bean-based egg substitute JUST Egg, which is now rolling out to foodservice and retail accounts, Tetrick acknowledged that sourcing and distributing the beans from Asia to North America was costly, while finding a ready market for other components of the beans aside from protein would be critical to making the numbers add up.

“Ultimately to get the unit economics to below the cost of production of a chicken egg we need to sell that starch for a decent amount.”

So who’s in the market for mung bean starch? “Quite a few people actually,” he said. “It’s used in Asia in noodles. Our business development team are talking to a handful of different companies about using it.”

Asked whether CPG companies were interested in using mung bean protein isolates from JUST in packaged food products, Tetrick said: “We’re talking to a handful of different companies on that including one larger player that I can’t name publicly right now.”

- Read FoodNavigator-USA on Friday for our final report from the Good Food Conference, featuring highlights from speakers including Uma Valeti MD, co-founder and CEO of cell-based meat firm Memphis Meats and Mark Post, PhD, MD, co-founder and chief science officer of cell-based meat firm Mosa Meat. We'll also delve into new consumer research into attitudes towards cell-based meat from food development firm Mattson.