NotCo granted US patent for AI technology, rolls out to new US retailers: ‘The momentum is just unbelievable’

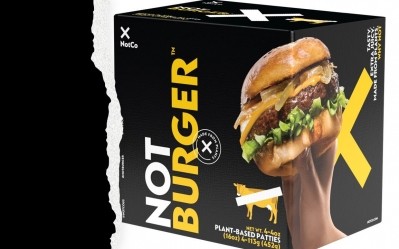

Billed as the ‘Impossible Foods/Beyond Meat of Latin America’ (its plant-based RebelWhopper is sold at Burger King and Papa John’s in Chile with more countries to follow soon), NotCo sells plant-based milk, burgers, mayo, and ice cream in major retailers and QSR chains in Chile, Argentina, Brazil; and is now moving into Mexico, Colombia, and Peru, with moves into Canada also in the offing.

Its velocities in Whole Foods in the US – where it debuted in late 2020 with NotMilk and secured national distribution within two months – are “above average for the category already,” said CEO Matias Muchnick, who spoke to FoodNavigator-USA after securing distribution at online subscription service Imperfect Foods.

NotCo - which now has offices in New York and San Francisco – also landed deals with Sprouts, Wegmans and other US retailers that should put the brand into 5,000 doors by the end of 2021, said Muchnick, who has just moved from Chile to New York to spearhead the company’s US expansion.

“The momentum is just unbelievable, people are loving the product (NotMilk 2% and whole) and we’ve had a lot of inbound interest [from other retailers].”

‘We are absolutely obsessed with cheese…’

Like Impossible Foods, Beyond Meat, and new player Climax Foods, NotCo’s strategy is to make affordable meat and dairy analogs that mimic their animal-based counterparts so precisely that consumers are not required to compromise… at which point the question becomes not why would you buy his products, but why wouldn’t you?

And only then will ‘alternative’ products start to seriously displace foods made from industrialized animal agriculture, argued Muchnick, who said significant strides have been made with plant-based meat, but that many plant-based dairy products – notably cheese, yogurt, and milk – still don’t deliver the taste, experience, and functionality that consumers get from dairy products.

“There is a huge opportunity there, especially in cheese. We are absolutely obsessed with cheese and we really think we can crack that better than anyone in this space.”

Enter Giuseppe… Making connections that ‘are not logical for humans’

Which is where Giuseppe – the name given to NotCo’s artificial intelligence – comes in.

“We try to understand in a very profound way what animal products are; not just the molecular information, the composition of the protein, but every dimension of the product, the spectral information, the physiochemical composition, the sensory information,” explains Muchnick.

And Giuseppe is then tasked with recreating this experience with plants, crawling through vast datasets (from internet recipes to USDA’s National Agricultural Library, to databases storing FTIR, gas chromatography, texturometer, physiochemical/viscosity/pH info) to make connections that “are not logical for humans.”

‘It’s not just about recipe generation’

And it goes way beyond flavor pairing (using science rather than a chef’s intuition to determine, say, that pineapple and blue cheese would be a great flavor combo as they both contain methyl hexanoate, for example), he argued.

NotMilk, for example, features pineapple and cabbage, two ingredients you wouldn’t expect to see in a plant-based milk, which Giuseppe identified as a combination that would generate lactones, aroma compounds found in dairy products. But Giuseppe is also tasked with finding ingredients and processes that deliver foaming, emulsification and other technical properties that make NotMilk deliver from a functional and sensory perspective, he claimed.

“It’s not just recipe generation; cooking processes are super important, so the algorithm needed to understand the impact of processing, which can generates new things like volatiles that you might not get from the ingredient in raw form but you get with heat, so we needed to train it to understand how ingredients work in combinations and in processes.”

NotCo recently raised an $85m Series C funding round co-led by Future Positive and L Catterton. Other high-profile backers include Jeff Bezos via Bezos Expeditions. The round brings its cumulative funding to $100m.

‘We needed to train it to understand how ingredients work in combinations and in processes’

While a team of enterprising chefs with a limitless supply of ingredients to work with might have stumbled upon the NotCo formula through trial and error, Giuseppe is much more systematic, and doesn’t approach a task with any pre-conceived ideas, said Muchnick.

Going beyond discovery and initial formulation, Giuseppe can also adapt to change, he said, citing the example of a switch in pea protein suppliers.

“They all taste slightly different because the isolation of the protein is different and so on, and NotCo can help you balance formulations when there is variable change, so it not just about discovery, it’s way more robust than that.”

He added: “We’re not the only ones using AI to solve problems in the food industry, but this gives us the ability to create plant-based products faster, better, and more accurate, than anyone else in this space.”

- Read Notco’s granted US patent (US10,915,818), which is one of a suite of patents the firm has filed (others are pending).

NotMilk 2% ingredients: Water, pea protein, chicory root fiber, pineapple juice concentrate, coconut oil, sunflower oil, virgin coconut oil, cabbage juice concentrate, natural flavors, salt, gum acacia, gellan gum, calcium carbonate, monocalcium phosphate, dipotassium phosphate, vitamin B12, vitamin D2.

Nutrition: A 240ml serving of NotMilk 2% contains 4g protein, 3g fiber, 3g sugar and 90 calories. (By comparison, a 240 ml serving of 2% dairy milk from Lucerne Farms contains 10g protein, 0g fiber, 14g sugar, and 140 calories.)

NotCo, which now has offices in New York and San Francisco (where part of its machine learning team is based), has recruited senior executives from Coca-Cola and Danone to support its expansion plans, and now boasts more than 16 team members in New York and 250 globally.

While having products that deliver on taste and texture is table stakes, says Muchnick, mission-driven brands are resonating more strongly with younger consumers in the plant-based meat space.

“What can the big meat companies say? I’m in this because I don’t want to lose market share? If a traditional meat company has been telling you that [animal-based] meat is the best thing to eat for the last 200 years and now they’re telling you that plant-based is a good thing, they [consumers] won’t believe you. Consumers care first about the product and the price, but also about who is behind it, and that’s where companies like NotCo win.”