“There’s urgency to what we're trying to do here and food is the fastest way to fix this, whether it’s [fellow panelists] Meati Foods, Air Protein, Orbillion Bio or Beyond Meat doesn't matter. We can empower people to do something proactive about climate. It would be great if you got a Tesla, but if you can't afford one, here's a $5 solution that you can pursue three times a day.”

But with mounting losses and declining sales, how much room for maneuver – and how much time - does Beyond Meat, a highly visible publicly held company, have to realize Brown’s vision and change the way we eat, something he himself has acknowledged will not happen overnight?

And what will it take to convince a broader set of consumers – who are pretty fond of meat – to switch to something that right now, is more expensive, and in some cases, not as tasty?

‘I was in fuel cells for a long time and there's a joke in the industry that fuel cells are good for the future, and they always will be’

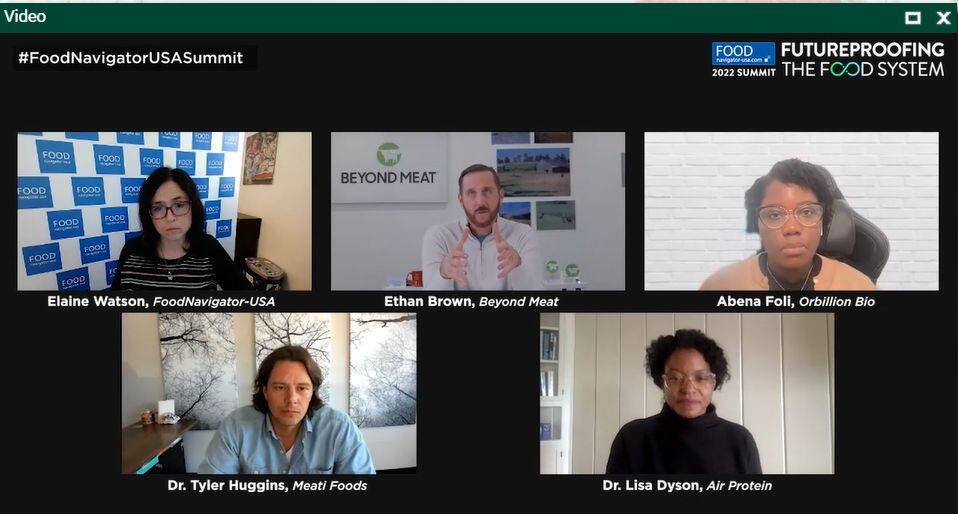

Speaking in a panel debate yesterday afternoon as part of ‘The Future of Meat’ segment in FoodNavigator-USA's Futureproofing the Food System virtual summit (register HERE to watch on demand), Brown rejected the notion that we have reached a technical plateau when it comes to plant-based meat.

“I was in fuel cells for a long time and there's a joke in the industry that fuel cells are good for the future, and they always will be. Innovation doesn't necessarily care for the timeframe of your career or whatever target you've set; these things happen in bursts.

“We are getting very close. We’re not there yet, but there's a lot of progress being made both within Beyond Meat and with other companies to get to the point where [meat alternatives are] indistinguishable from animal protein. It’s entirely possible; it's just a question of time. I can't give you deadlines, but we have new versions of our burger, for example, which are phenomenal, and we'll keep getting better until the point we’re indistinguishable.”

‘Let's not judge the category until we get to price parity’

As for pricing, he said, “Let's not judge the category until we get to price parity. At that point, then I think we have an opportunity to say, okay, it tastes just like animal protein, it’s healthier for you, has enormous environmental benefits, if you can do it at the same price, a lot of people are going to make that choice.”

‘What’s holding us back is [lack of] scale’

So when will the sector achieve price parity? And if it’s logically more efficient to cut out the middleman and eat plants rather than feeding them to animals, why is plant-based meat more expensive?

“What’s holding us back is [lack of] scale,” said Brown. “If you look at JBS or Tyson or Cargill, they're running so much material through their systems and they have generated tremendous efficiencies, while we're just starting out.”

‘There's so much to be done to wring cost out of the system’

But are there also improvements in manufacturing processes that are needed to drive efficiencies beyond mere scaling?

“Absolutely,” added Brown. “That's why for anyone who's interested in lean manufacturing, this is like Disneyland, there's so much to be done to wring cost out of the system. Our own production system does have too much batch [processing] in it, it needs to go to [a] more continuous [process] and all of us will get to the point where it's a much more continuous, steady flow, operational process and that will drive costs down.

“But again, what excites me so much about this is that the animal is not changing. We are driving innovation against a static target.”

Asked about texturizing technology, he said: “Extrusion is such a diverse technology, but I'm not an engineer, and I'm not wedded to any particular technology, I'm wedded to the outcome. So if there's something that does a better job of realigning proteins for flexing the muscle structure, you can guarantee I'm looking at it.”

‘A lot of incumbents and interest groups… are out there saying, Look, this stuff is processed, it's fake’

What is getting lost to the consumer, however, is the basic message that plant-based meat is better for human health and for the health of the planet, he argued. “A lot of incumbents and interest groups… are out there saying, Look, this stuff is processed, it's fake and taking out ads in the Wall Street Journal or the New York Times, and trying to seed doubt in consumers’ minds about whether our products are healthy.

“The animal processes are largely conducted in factory farms, with antibiotics and hormones, whereas in our case, it's a very simple system of separating protein from plants and then running it through heating, cooling and pressure.

“All we can do is do what we've always done, which is go back to science and go back to data,” added Brown, who has just announced a multi-year agreement with the American Cancer Society - which recommends limiting processed meats, red meats and choosing alternative protein sources - to advance research on plant-based meat and cancer prevention.

“So we teamed up with Stanford, we have a five-year program there, and we're doing tests with a statistically significant number of people… and [in the ‘SWAP-MEAT’ study, volunteers who ate] Beyond Meat [rather than animal protein for eight weeks] had a clinically significant drop in LDL cholesterol and a drop in TMAO, which I think is even more interesting, as it’s a compound that’s associated with heart disease and certain cancers.

“We’re continuing to do studies with the university and across the medical community to show the benefits of plant-based protein. But it’s not new; if you look back in history at the Seventh Day Adventists, there's a population in the United States that is living longer than most and they have a deep history of consuming what we call plant-based diets.”

The environmental message ‘is probably not getting through to the degree that it needs to’

The environmental message “is probably not getting through to the degree that it needs to,” he speculated. “But the way I think about this is always around taste being the first driver, the second is health, and the third is really around climate.

“But I think this is a period of dislocation for the consumer... If you look at our pricing in the supermarket, relative to animal protein, take beef, in many cases we are about $3 more and in this environment, it's very difficult for the consumer to make ends meet.

“And so the types of decisions people were making 18 months ago, two years ago, are going to be more complicated right now. We're at the very beginning of this transition to a plant based meat outcome, and one that is going to see turbulence and we're seeing it now and we'll get through it.”

Abena Foli, Orbillion Bio: ‘We are all trying to address the same problem with different solutions’

Whether you’re in cultivated meat, microbial fermentation, or plant-based meat, said Abena Folio, head of regulatory affairs at cultivated meat startup Orbillion Bio, “We are all trying to address the same problem with different solutions – how do you feed 10bn people by 2050 in a sustainable way?

“So saying that the protein space is dead or tapering off is not an accurate take, because we're all at different stages. If you look at investment, just last year out of the $5bn that was put in the alternative protein space, $2bn went to cultivated meat.”

Dr Lisa Dyson, Air Protein: ‘We are scaling up a way to make food that doesn't require any arable land whatsoever’

At base, said Dr Lisa Dyson, founder and CEO at Air Protein, which is using carbon dioxide (rather than an agricultural feedstock such as sugar) to feed bacteria that are highly efficient at making protein in a process involving water and electricity the company bills as carbon negative, “We have to figure out how to grow food without using more greenhouse gases than the entire transportation sector…

“And we have to figure out how to do it without using so much land, and so we are scaling up a way to make food that doesn't require any arable land whatsoever. Instead, it starts with the elements that make up those inputs [used in traditional fermentation such as sugars]. What is sugar made out of? Carbon, hydrogen, and oxygen. And so we essentially feed the cultures those elements and then we're able to make different nutrients, so it's a type of elemental fermentation.”

She added: “The economics… indicate that we'll be able to make ingredients, proteins, fats and beyond, at a comparable or lower price than what's in the market today. Carbon dioxide is an integral part of the food industry, but ultimately we’ll co-locate next to fermentation, as fermentation has carbon dioxide as a byproduct.”

Dr Tyler Huggins, Meati Foods: ‘I would argue that this is one of the most efficient ways to produce meat out there'

Meati Foods, which is making whole cut meats from fungi in a fermentation process using sugars as feedstocks, has been focused on scalability from the outset, said co-founder and CEO Dr Tyler Huggins.

“Fungi are really good at taking simple elements and producing a truly unmatched nutritional profile. We're doing third party analysis with Planet Forward right now and even equating the land that's required to produce the sugar [to feed the fungi], we're orders of magnitude less than beef and we're quite a bit less than chicken as well. And we're just going to continue to get better and better and better.

“I would argue that this is one of the most efficient ways to produce meat out there. We simply take this whole biomass, which has this threadlike, fibrous texture, realign it and create whole cuts, flavor it, and that's it. The challenge is making sure we can do this in a continuous fashion at the scale required.”

Abena Foli: ‘How do we reach the consumer in a way that's not scientific for them to understand what we're doing?’

But does it matter if these products are more sustainable if consumers aren’t buying them?

Whether they’re in plant based meat, cultivated meat, or microbial fermentation, said Foli at Orbillion Bio, players in this space have to find ways of meeting consumers where they are.

“The key question is how do we reach the consumer in a way that's not scientific for them to understand what we're doing. So I live in the great state of Texas where we have a lot of farmers and meat production, so when people ask me what I do, they say ‘Is that the lab grown stuff?’ We have to find a way that makes it approachable for them because once you lose the consumer on the educational piece, price doesn’t even matter.”

At Meati Foods, saidm Dr Huggins, “Growing up in in Montana, if you didn’t have center of the plate meat, it wasn't a meal, so the question for us is how do we provide something that's a true drop in replacement?

“The texture [of a Meati Foods steak is] is very similar [to a conventional steak]. Does it have to be exactly the same? I don't think so. It needs to be enjoyable to eat and easy to cook. To convert as many people as we can, it also has to have that quality of all natural, and a superior nutritional profile.”

Dr Lisa Dyson: ‘We want to be able to supply the industry with a suite of ingredients that have extra sustainability metrics associated with them’

At Air Protein, said Dr Dyson, “The first ingredient we’re commercializing is high in protein, it’s highly digestible, it has all the essential amino acids, and it’s rich in vitamins and minerals, including vitamin B12. But we're developing a platform that brings a diversity of ingredients with different functional properties that have different oil- and water-holding capacities and that allow for the formulation of different types of products. To have the impact we all want to have, we want to be able to supply the industry with a new type of ingredient or new suite of ingredients that have extra sustainability metrics associated with them

“We're scaling up our demonstration facility as we speak, and we’ll have announcements about both the demonstration facility as well as our commercial timeline next year.”

In terms of labeling, she said, “There are two types of two approaches that companies have taken when they've done fermentation. One is to name the culture, and the other is to have a new name, so mycoprotein would be an example of that. We're almost at the finish line with the regulatory process, so I hope to be making some announcements about that soon.”

REGISTER for free HERE to watch the segment, ‘FOOD TECH IN FOCUS: The Future of Meat’ on demand.