Kirkness, the Canadian founder and CEO of Catchmate, has a simple ambition: to ensure his recently-launched Catchmate CM Plant Floor system delivers innovation to factory floors via cutting-edge software.

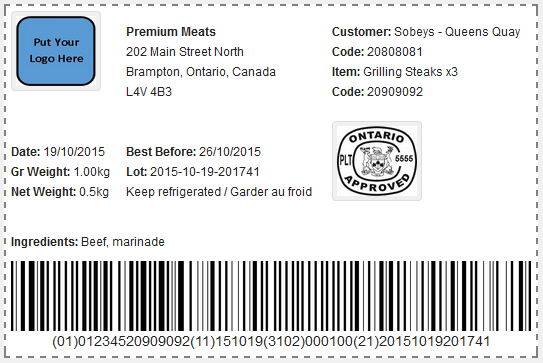

His weighing, labelling and tracking system, launched in August 2016, automatically assigns each individual product with a serial number that can be used to trace manufactured products back to the day, hour, minute and second of production.

A number of meat processors in Canada are testing the software and Kirkness said the system’s ability to help manage a food safety recall could be a major boon for the meat industry.

Capital gains

“Catchmate is useful in the event of a recall because it contains both customer and lot-batch information in one place,” he said.

By running a Google-style search on the Catchmate’s system, processors can pinpoint a specific production date and time. Alongside this, the serial code also reveals the customer the meat was produced for, making it incredibly useful to determine who will have received the meat.

But the million-dollar question remains – will meat processors save money? “Yes,” Kirkness said, who added: “The more specific a company’s response [to a recall is], the smaller the window the recall will apply to. Having a system that allows you to search by date and time, down to the hour and minute of production, ensures the recall window is as small as possible. Without automated traceability, safe products can be designated unsafe out of precaution and required to be called back, which is where the extra expense typically comes from.”

Meat plant modernisation

The system has other functionalities that could make it useful to meat processors too: research from Catchmate suggests nearly 75% of recalls are due to mislabelling, not food safety. Catchmate has a label preview function to provide a final viewing opportunity to prevent costly mislabelling mishaps.

The software is being tested by several meat processors in Canada, but Kirkness said he was already thinking about other tech solutions: ideas include data systems on meat temperature, pH balance and quality control testing. It’s all part of a plan to automate meat line operations. And with half of all US food recalls costing businesses more than $10m a year, according to Swiss Re, systems like Catchmate could help meat processors optimise recall management.