“That blanching water used to go to the sewer until a couple of years ago,” Rico Lansbergen, sales manager at Netherlands-based Scelta Mushrooms, told FoodNavigator-USA at the IFT Food Expo in Las Vegas last month.

“Then we discovered that a lot of the contents of the mushroom was in the fluid,” he added. From this fluid come two different ingredients—liquid mushroom concentrate, and spray-dried mushroom powder.

These ingredients are not just for mushroom-flavored products. Rich in natural glutamate, Lansbergen said the ingredients enhance flavors in general, which means formulators can use them to reduce salt or replace monosodium glutamate (MSG) or autolyzed yeast extracts if they wish to create a ‘clean label’

product, Lansbergen said.

Innovating in preservation technology

The umami-flavoring ingredient is just one of Scelta Mushroom’s many products, most of which derive from white button mushrooms grown in the Netherlands. The company is based in Venlo, a region where Dutch white button mushroom cultivation is concentrated.

Family-owned Scelta Mushrooms was established in 1993 by Jan Klerken, the company’s current CEO, who came from a mushroom growing and canning family. It touts itself for working closely with small Dutch mushroom growers, grown using compost from the livestock industry.

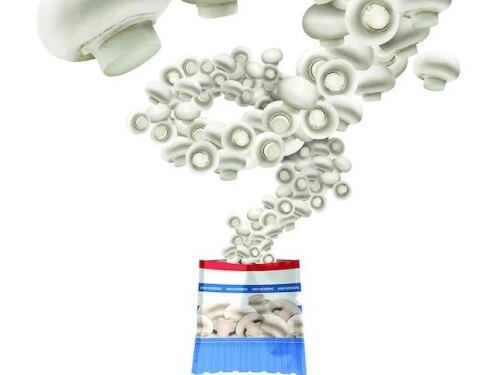

Its hallmark product is preserved mushrooms—either in cans with brine, frozen, or dried. One of the latest preservation innovations from the company is the patented Ecopouch, developed as a response to consumers shying away from artificial preservatives.

“The traditional processes of food preservation are on their last legs,” according to the company. “A classic technique to preserve is to add salt and various acids—labor intensive to produce, with high wastage.”

All the additives also alter the taste of the mushrooms. With the Ecpoouch, the mushrooms are packed first, then boiled in their own juice. The final product—designed mainly for foodservice and other prepared food customers—are mushrooms with the closest quality to the fresh kinds, but with a longer, shelf-stable life.