The first food colors were made from plants, but were gradually replaced by petrochemical-derived artificial colors such as Red #40 or Yellow #5, thanks to advances in synthetic chemistry. By the end of the 20th century, however, natural colors were back in vogue, with manufacturers returning to plants (beets, annatto, turmeric), or in some cases single-celled microorganisms that naturally produce vibrant pigments (bacteria to make orange carotenoids, spirulina to make blue colors etc).

But extracting colors from plants is not always practical or sustainable, while microbial fermentation (using yeast, fungi, algae or bacteria cells etc) can’t produce everything the food industry wants, Debut Biotech founder and CEO Joshua Britton told FoodNavigator-USA: “Many of the great ingredients we find in nature are too complex to be made inside a cell, so they’re still being extracted from plants."

Targeting ‘the most difficult, high-value color ingredients in the market’

He added: “We’ve found that our technology is able to add real value for the most difficult, high-value color ingredients in the market, since our cell-free platform unlocks a level of complexity and sustainability that’s previously been inaccessible in color manufacturing.

“We’re doing better on every metric — cost, quality, sustainability, and speed, in addition to creating colors that have a range of functional benefits. While extraction and fermentation techniques have made improvements in the sustainability and efficiency of color creation, they’ve largely been incremental improvements.”

‘Colors that are very hard to find or are largely inaccessible in nature’

But could Debut Biotech’s technology enable the production of color shades that are not currently available from natural sources?

“Absolutely,” said Britton, who co-founded Debut Biotech in early 2019 and recently struck a deal with DSM to explore a range of high-value ingredients.

“Cell-free allows us to much more rapidly test different approaches to creating colors, especially those which are very hard to find or are largely inaccessible in nature. Consumers want the strong colors they’ve come to expect in their food and personal products, but now they also want them to be safe and sustainable.

“This is an area we’re especially excited about because we know our cell-free platform can meet the challenge. In the future we look towards solutions such as how small modifications to the product can, say, alter a dark red into a lighter pink for different applications.”

'Traditional biomanufacturing processes are limited'

The multi-million-dollar joint development deal with DIC, spanning several years, will enable Debut Biotech and DIC to leverage advanced biomanufacturing approaches to produce natural color ingredients across many industries, from food and cosmetics to health products, said Britton.

“The market for naturally derived and sustainably produced ingredients is growing exponentially, but industries’ ability to meet those needs is limited by traditional biomanufacturing methods.”

“Our organization has identified sustainability as an overriding company priority, but we’ve been limited by the constraints of traditional cell fermentation. Debut Biotech’s platform removes these constraints, enabling us to increase and diversify our color products for a wide range of applications,” added Kiyofumi Takano, general manager of new business development at DIC.

Cell-free biomanufacturing

So what is ‘cell-free’ biomanufacturing?

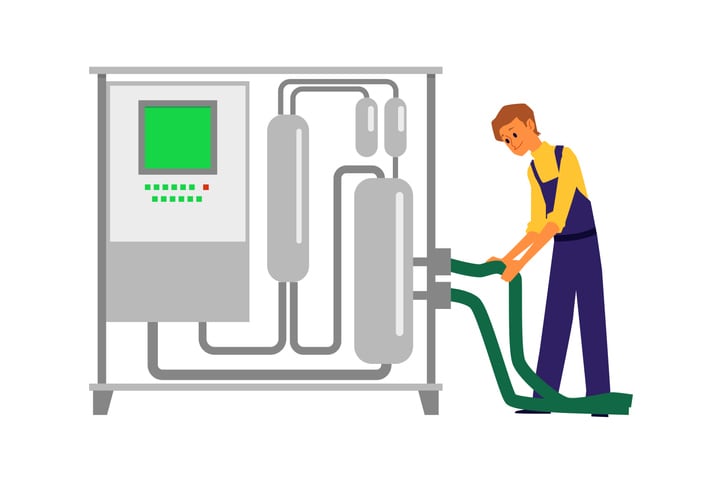

At Debut Bio, Britton is taking some of the machinery of cells (custom-designed enzymes, nature’s tiny biological catalysts) and immobilizing them (essentially fixing them in place) such that they can convert low-value materials such as glucose into high-value ingredients such as colors, in a continuous process.

This allows Debut Bio to operate across a wider range of conditions (pH, temperature) and allows for metabolic transformations that are not possible in cellular microbial fermentation systems, he claimed.

“We also don’t need gigantic fermenters. We flow renewable feedstocks through our [much smaller] reactors and out the other side comes functional food ingredients.”

'Immobilized' enzymes

While enzymes – which themselves are made from host microbes such as E. Coli or yeasts – are not cheap, Debut Bio has come up with a technique to deploy them more efficiently, he said.

“Once we create the protein [enzyme] once, we don’t need to keep creating it, we can stick it to a bead [to ‘immobilize’ it] and use it and use it again. We chemically bind the enzyme to a resin support so that it will remain attached while the fluid is flowing over the protein. This is in contrast to a non-immobilized enzyme/protein where it is floating around freely in a reactor.

“We do this because we can pack a huge amount of enzyme into a small place and do effective bio-transformations. The enzymes are often also more stable, can be reused (we have reused one for 30 days before), and we don’t have to worry about separating the enzyme from the final food ingredients.”