WATCH: Apeel CEO: ‘The way I think about it is that waste is this invisible tax on the entire food system…’

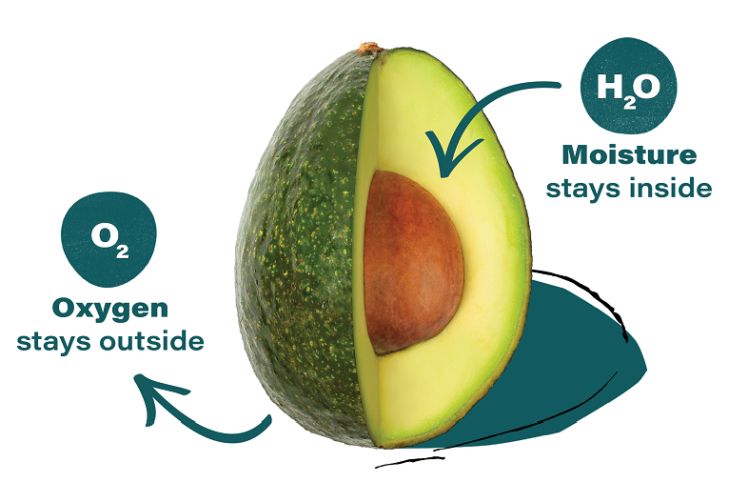

But success didn’t come overnight for a company now considered to be one of the hottest properties in food/agtech, says Apeel Sciences founder and CEO Dr James Rogers, who worked out how to slow the respiration rate of fruits and veggies by applying an invisible, plant-based edible skin that keeps moisture in, and oxygen out, as a materials science PhD student at UC Santa Barbara.

“I came straight out of university and thought, wow, if we could give food more time by using food to preserve food, that would be a really important technology,” he told FoodNavigator-USA at the firm’s HQ in Goleta, Calif.

“And so, we started knocking on doors saying, ‘Hey, we have this amazing technology that will reduce waste and benefit your customer.’ And a lot of the responses we got were, ‘Why would I want my customer to have more time? The garbage can is my best customer. If they throw away less food, they're going to buy less food from me, so why would I want to introduce this technology?’

“And it just struck us that we have a challenge here that goes beyond a technical challenge. We're introducing a product in a market that doesn't exist.”

The business case

Fast forward to 2021, however, and the conversations have changed significantly, said Rogers, who now stands at the helm of a company with a valuation north of $2bn, with operations in three continents countries and customers from Kroger and Walmart to Costco and Edeka.

For a start, the company has demonstrated that business case for using Apeel is compelling at every step of the supply chain, he points out. In the case of long English cucumbers, for example, applying Apeel means firms can ditch the plastic shrink-wrap; while for asparagus, the extra shelf-life means it can travel by sea instead of air, without the use of controlled atmosphere.

Avocados treated with Apeel have up to 50% longer shelf life, slashing retailers’ shrink and giving consumers more time to enjoy them at peak ripeness; while for limes, Apeel can triple shelf life, giving growers and distributors access to new markets.

‘People often complain about the flavor of their tomatoes… that’s often because they're picked when they're immature’

But economics aside, tackling food waste is increasingly valued in and of itself, points out Rogers (“The scale of the food waste challenges is staggering…”), who says there are also exciting flavor and nutritional benefits to be had if you can leave fruits on the tree, or tomatoes on the vine, for a little longer, rather than picking them before they are ripe in order to ensure they make it through the supply chain.

“People often complain about the flavor of their tomatoes… that’s often because they're picked when they're immature and green... The problem is that the shopper ends up with a tomato that doesn't taste very good.”

In other cases, just being able to extend shelf life a little might mean you don’t have to import fruits from further afield, he says.

“For example, for lemons, there are gaps in the season, where if the food just had enough time, instead of needing to import citrus from across the world, you're able to take that [domestically-grown] produce that was harvested a couple of weeks before and have it available for store shelves during that period of the year when otherwise you would be forced to look somewhere else.”

‘Fruit is a living breathing thing…’

The key to Apeel's success is finding that delicate balance between slowing down the respiration rate of fresh produce through essentially mimicking what fruits such as oranges do already (producing a kind of ‘skin’ called 'cutin') and shutting off the respiration process completely, explained Rogers.

“Fruit is a living breathing thing. And so yes, we can slow down the rate that the fruit is respiring [taking in oxygen and churning out carbon dioxide] and it allows the fruit to have more life. But you don't want to stop it completely because then the produce goes anaerobic and it doesn't taste good. It's really unhappy.”

So, is there a magic number Apeel is looking for when it seeks to extend shelf life? “The benchmark tool we use today is refrigeration [which slows down the rate of respiration], which can effectively quadruple the shelf life of fruits and vegetables,” said Rogers.

“And so we will be able to replace refrigeration when we're approaching that quadrupling of shelf life using the technology. For certain categories we’re [already] around that mark, and for certain categories, we have more work to do.”

What is Apeel and how does it work?

Supplied as a powder that can be mixed with water and sprayed onto produce, Apeel's invisible skin is made from plant extracts (primarily lipids from agricultural by-products such as grape seeds) which self-assemble into structures - an edible ‘skin’ of consistent thickness - that allow Apeel to effectively slow down the respiration rate of produce by keeping moisture in, and modulating the rate of oxygen and carbon dioxide transmission to create an 'optimized microclimate' for each type of produce, explained senior biological scientist Savannah Braden.

“Fruits are biologically engineered to break down because they have seeds in them, that's how they propagate, and so we're kind of fighting nature as we try to make them last longer. Things like cucumbers don't ripen, they just kind of decay. There’s a bunch of molecular machinery that's being turned on by water loss and oxidative stress.

“Our barrier is in the order of a 1,000 nanometers, so it's super, super thin, so all it does is reinforce the skin that the produce already has, but it works really well as it's limiting those two things [water loss and oxidative stress], but then further downstream, all the molecular cascades that trigger softening and color change are also being slowed down.”

There are as many types of Apeel edible skin as there are different types of produce (one size does not fit all), and Apeel's solutions are then further customized based on varietals, and the conditions in which the produce is stored and transported, added Braden.

“A lot of it has to do with the surface type of a piece of produce, but we do see variants and performance even across a season because a piece of produce is dependent upon all kinds of elements including the weather and the state of the tree at that point in the harvest.”

‘We're no longer doing as much of a guess and check’

But given the team’s growing knowledge and expertise of the respiration rates of different fruits and vegetables, the 'guessing' involved at the start of every new product development process becomes more and more educated, she said.

“Even within a category we're getting better at knowing what we need throughout a season, because we're no longer doing as much of a guess and check.”

As the conditions in Apeel’s labs clearly differ from the conditions fresh fruit from Chile might be subjected to as it travels to US supermarkets, for example, the company has also developed sophisticated monitoring techniques to track the conditions (temperature, humidity, etc.) in which produce is being transported, in real time, and then mirror those conditions in its facility so that it can develop solutions that it knows will work in the field, added marketing sciences SVP Jason De Turris.

“We take all that data so we can understand the optimal coating and formulation for that supply chain.

"We're building the biggest knowledge base on plant physiology that I'm aware of, but there will always be unexpected things that happen in a supply chain. Take cucumbers, which are 95% water. If those go to a 32 degree freeze in a supply chain that we aren't aware of, they'll start to deteriorate [regardless of what they’re coated in].”

'Factors of freshness'

According to De Turris, “One thing we’re doing now, outside of the lab, is a lot more market research with shoppers around the world. We call it 'factors of freshness.' So we're understanding for each of the categories when they're in store, what are consumers looking for as far as color, firmness, and flavor, and then when they're home, what are they hoping to enjoy?

“And so now we're also able to take that feedback and feed that back upstream into our product formulation.”

As for R&D work, Braden is hopeful that next-generation versions of Apeel’s edible skin may also tackle mold and fungus directly. Right now, Apeel has an indirect impact on mold (which invades when produce's defenses are weakened as they dehydrate and oxidize) by slowing down the decaying process, but future versions could tackle mold directly, she said.

“We have a microbiology function which seeks to understand how fungi that cause decay are interacting with produce and potential future products could have antimicrobials that are also derived from plants.”

Competition: 'It's all about thinking about how would nature solve this problem'

Asked about competitive solutions to extend the shelf life of produce, such as silk proteins (an approach developed by Mori) or approaches that utilize 1-MCP (a chemical that inhibits the production of ethylene, which triggers ripening, softening, and color changes), Braden said Apeel had the advantage of being scalable, and plant-based.

According to Rogers: "When we build our formulas, we only use ingredients that are found in every bite of fruit and vegetable that we eat every day, because then we can tell consumers that we're using food to preserve food.

"It's all about thinking about how would nature solve this problem, because if we can mimic the way that nature would solve this problem and use ingredients that nature has already come up with, then we're using a solution that we know intrinsically works with the natural world and not against it."

Perhaps the most effective tool to demonstrate Apeel’s business case is time lapse technology, whereby Apeel lines up treated and untreated produce side by side, films what happens over a period of days or weeks, and then creates a time-lapse video, so viewers can see exactly how the samples compare at day 3, 6, 10, 20 and so on.

Apeel’s time lapse room at its Goleta HQ features cameras mounted on tracks above a rack that holds produce samples, a stepper motor that slides the camera between samples, and several Raspberry Pi mini-computers that control the camera and store images, which are then pulled to produce analytical reports.

Apeel also records and analyzes data about color, texture, size and volume, and feeds this back into its computer systems to inform the development process (put another way, it’s not just something fun to show potential customers as part of the sales pitch).

Life cycle assessment

When Apeel thinks about sustainability, it looks carefully at its own operations so that the environmental impact of producing, distributing, and applying its edible skin doesn’t outweigh the benefits it creates for customers, said Dr Jessica Viera, senior director, sustainability.

A majority of the energy consumption for Apeel - electricity and/or natural gas - occurs during product application, as it is used to heat the Apeel solution, power fans and conveyer belts, and heat air in a drying tunnel to dry the product onto produce, for example.

“That’s exactly why we use life cycle assessment to take into account both the benefits our products enable such as reducing food waste, eliminating the need for plastic packaging, and enabling more efficient logistics, as well as everything required to make, distribute and apply Apeel," explained Viera. "Ultimately we’re ensuring that our products have the strongest net environmental benefits when our own footprint is factored into the equation.

“One of the biggest learnings from our [May 2020] life cycle analysis [assessing the environmental impact of 1kg of Apeel-treated produce consumed in US or EU households vs 1kg of produce without Apeel] is how reducing food waste can lead to avoided greenhouse gas emissions throughout the entire supply chain.

“Most people associate food waste reductions with fewer landfill emissions, but by reducing waste Apeel prevents the need for additional resources to be used for production, harvesting, storage, and distribution.

“When we use fewer resources to meet the same demand for food, the environmental impacts of the whole system decrease.”

All photos courtesy of Apeel Sciences.