Josh Tetrick, CEO of the San Francisco-based firm is in early talks with at least 10 global meat and feed companies across South America, Europe and South-east Asia to bring industrialised production efficiency to lab-grown meat.

It plans to grant commercial product licenses to beef, pork and chicken processors to use its technology to cultivate lab-grown meat, as the firm seeks to plot a path to sustainable protein production.

The economic relationship would look like this: Hampton Creek offers meat processors commercial product licenses for a pre-agreed timeframe in exchange for royalties and upfront payments when certain milestones are reached.

Conscious consumerism won’t change the world

Its decision to tap up global meat companies is simple: it needs to radically scale up efficient production if it is to have a marked impact on driving meaningful change in how meat is made.

“Ultimately anything we do in this space is irrelevant if we cannot make it as, if not more, affordable than the core categories of conventional meat today - it’s a waste of our time,” said Tetrick.

“I’m not a big believer that conscious consumerism is going to initiate a fundamental transformation. I think what creates a transformation in how folks eat is if you create products that taste better, are more affordable and connect with people.”

Lab-made meat to hit market in 2018

This is where the meat companies with their huge efficiencies can help Hampton Creek produce lab-grown meat at prices consumers will not baulk at.

Due to commercial sensitivities the companies cannot be disclosed, but Tetrick said the firms are ones GlobalMeatNews readers would be “very familiar with”. Firmer details are expected within the next 12 months.

By around this time, its first lab-grown meat product should hit the US market.

Eitan Fischer, director of cellular agriculture at Hampton Creek, said the company had made “significant progress” in their clean meat application with the first product, likely to be poultry, set to launch toward the end of 2018.

Foodservice is a more likely avenue than retail, but a final decision is yet to be made.

Manufacturing costs remian a big factor and the company expects the first product will be around 30% more expensive than conventional meat.

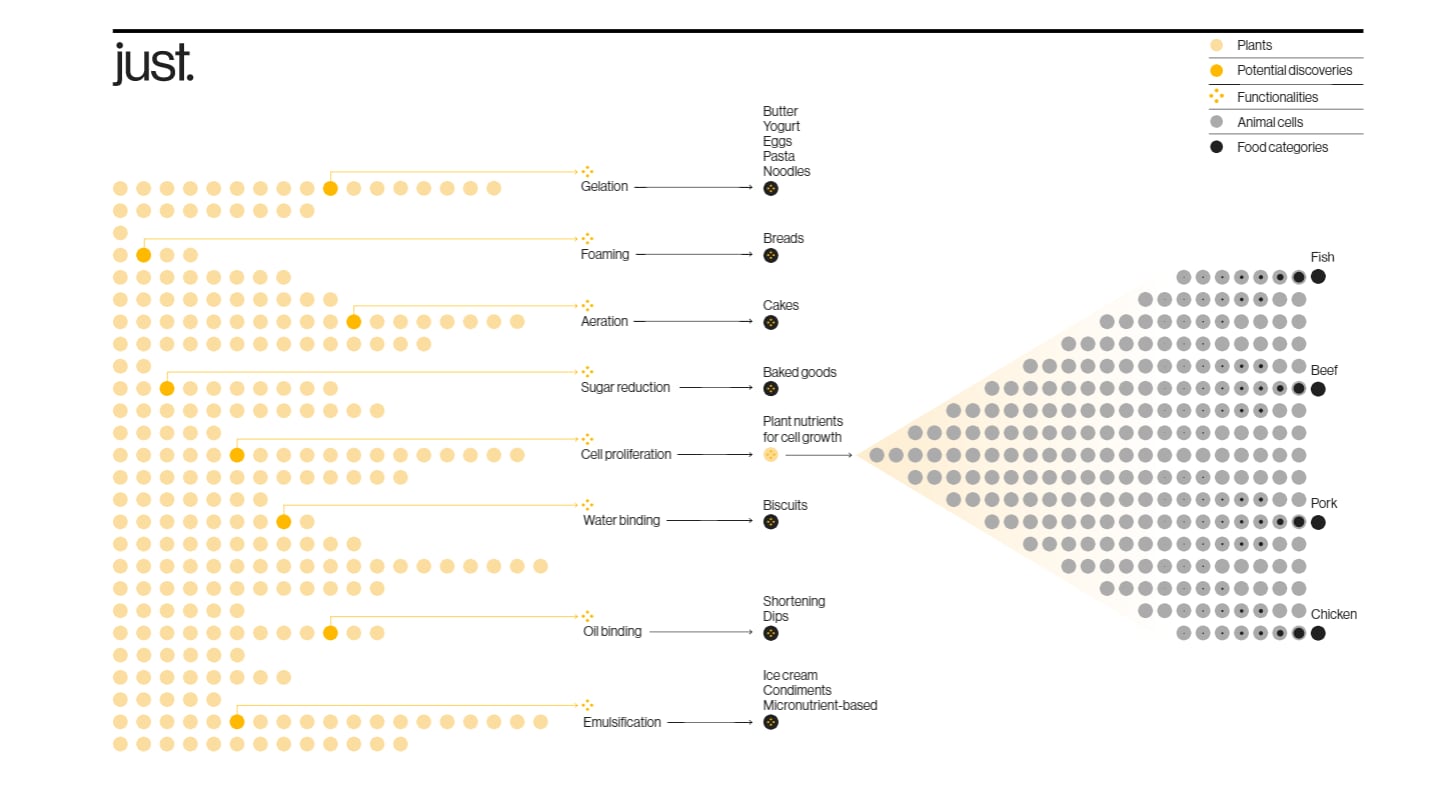

Both Fischer and Tetrick are hard at work in boardrooms as well as the company’s analytical chemistry suite and robotics laboratory looking for protein in plants to provide nutrients for animal cells to grow efficiently. This will help to make meat production more sustainable.

It’s only been a couple of months since the company announced its entry to the lab-grown meat market in June, although it had been working on clean meat solutions for over 12 months.

The company understands that it “cannot be successful without the meat industry”. When asked if working with global meat companies to utilise production efficiency is the best way to drive an upturn in lab-grown meat efficiency, Tetrick said: “That is exactly what we think the path is to enable folks to eat in a better way.”

Interested in the future of cultured (a.k.a.'clean') meat?

Join Hampton Creek's director of cellular agriculture Eitan Fischer at FOOD VISION USA in Chicago in November, where he will be speaking on a food and farming panel debate with Maple Hill Creamery founding farmer and CEO Tim Joseph and Suncrest USA CEO James Day, to address questions including:

- Will cultured (a.k.a. ‘clean’) meat present a threat, or an opportunity for conventional meat companies, and how will consumers respond?

- How big a role will cellular agriculture play in our food system in the future?

- Is a significant shift towards organic farming practical or desirable in the US?

- How big is the grass-fed meat and dairy trend likely to become?

- Is ‘regenerative’ farming a niche for foodies or a wider movement we’ll all be talking about in 10 years?

- Where does hydroponics fit into the broader food system?

The event will also feature Dr Liz Specht from the Good Food Institute.