Full results will be published in the fall, but an early look at a comprehensive lifecycle assessment (LCA) of Ingredion’s stevia sweetener operations suggests different production methods for Reb M have quite different environmental impacts, but also highlights the challenges around how best to communicate LCA data in a responsible manner.

Currently, there are three main production methods for Reb M, which has become the most sought-after stevia sweetener because it has the most sugar-like taste, but is typically present in very low levels in the plant.

- Leaf: Reb M extracted from stevia leaves;

- Bioconversion: Reb M made with stevia leaf extract as a starting material that then undergoes an enzymatic conversion process to get to Reb M;

- Fermentation: Reb M made via fermentation of sugars with genetically engineered yeast.

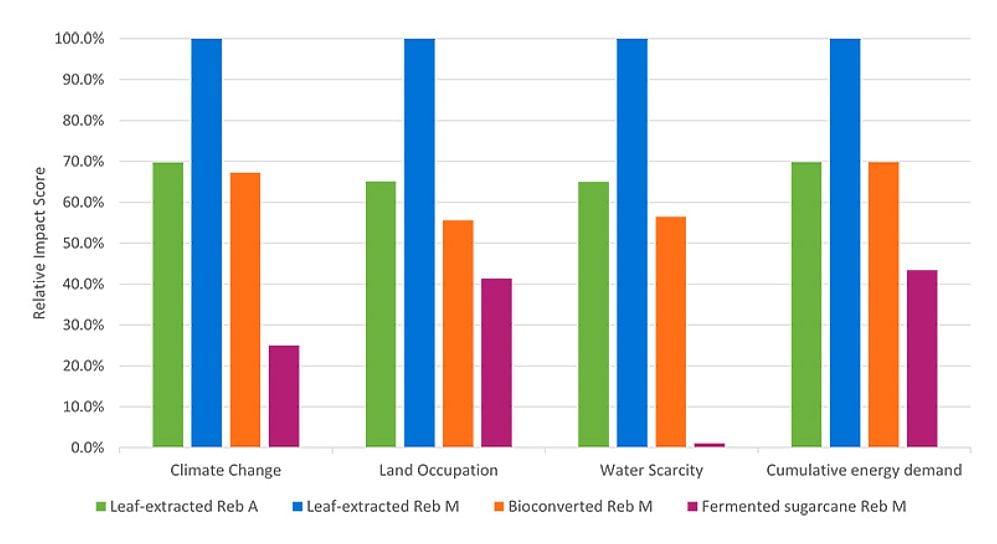

According to Ingredion, which offers customers Reb M made from all three production methods, Reb M from fermentation and bioconversion outperformed Reb M extracted from the leaf across all four key sustainability metrics (GHG emissions, land use, water scarcity, and cumulate energy demand), with the fermentation-based approach (which doesn’t involve stevia plants at all) generating the lowest environmental impact by some degree (see chart below).

Customers that want to see the impact of switching between different sweeteners on any of the four key metrics used in the LCA (GHG emissions, land use etc) can use a ‘sustainability calculator’ on Ingredion’s website.

Communicating LCA data: ‘There's four different attributes here, which one's the most important, and should we aggregate them?’

So what is the best way to communicate this data set, and LCA data more generally?

While customers – and consumers - want to know whether product X is a more sustainable choice than product Y overall, there’s not always a clear-cut answer, Kurt Callaghan, global strategic director for sugar reduction at Ingredion, told FoodNavigator-USA.

Maybe product X has a super-lower land or water footprint, but very high GHG emissions, while product Y uses a ton of land and water, but has super-low emissions? Which has the bigger environmental footprint?

“I still think we're determining that as an industry,” said Callaghan. “There's four different attributes here, so which one is the most important, and should we aggregate them? The short answer is no.

“Greenhouse gases is by far and away where we’re seen the most focus from our customers perhaps because it’s the easiest to measure and understand, but as we get deeper into ESG [Environmental, Social, Governance] initiatives across the globe, water scarcity in some geographies is going to be the most important factor, so really it depends. It's going to be situational.”

‘As an industry we're still very early in collectively, fully understanding how to best use this type of information’

Given that so many food and beverage companies are now making sustainability claims based on LCA data where they may be cherry-picking the ‘good bits’ or commissioning ‘pay-to-play’ LCAs that aren’t worth the paper they are written on, how are industry stakeholders and consumers meant to navigate all of this and make informed decisions?

“We’re continuously being asked for more sustainability information,” said Callaghan. “But I would say as an industry we're still very early in collectively, fully understanding how to best use this type of information.”

‘We can’t improve what we don't measure’

In general, said Callaghan, “We see a lot of greenwashing out there but in the investment community, we've seen a lot of push-back against that recently.

“I think everyone is still kind of early in the LCA process, but from our perspective, we can’t improve what we don't measure and this is a starting point that can help us identify where we can invest to make the biggest impact.

“So two examples where we are doing that is breeding stevia varietals with higher levels of Reb M [so you get higher yields from the same land/water/inputs], and also using more of the plant material, either as an energy source or as fertilizer and so on.”

Sustainability and b2b purchase drivers: ‘It’s really case by case, customer dependent or even brand dependent’

As to how the LCA data on Reb M may influence purchasing decisions, some customers, said Callaghan, will carry on buying Reb M extracted from stevia leaves (which is the most expensive and has a higher environmental footprint than bioconversion or fermentation) because they want to be able to say ‘stevia leaf extract’ on their labels (which you can’t do if you’re using Reb M from fermentation, for example).

For other brands, price is the driving factor, and fermentation-based Reb M is the cheapest option which also happens to have the lowest environmental footprint, he said. Others may be focused on whether their sweeteners come with Non GMO Project verification (which applies to Reb M from leaf extract and from bioconversion, but not from fermentation).

However, for some customers, LCA information is increasingly informing decision-making, he said: “It’s really case by case, customer dependent or even brand dependent. For some brands, sustainability is going to be what's most important.”

Assumptions upon assumptions

While there is a lot of good, published, peer-reviewed LCA data out there in various databases about all kinds of ingredients, said Callaghan, the devil is always in the detail.

So for example, sugarcane sourced from one part of the world may have a dramatically lower footprint than sugarcane from another, and once you start drilling down into datasets that attempt to provide a standard footprint for a given ingredient, you are basically looking at a series of assumptions.

“The feedstock for our fermentation-based Reb M [made in partnership with synthetic biology partner Amyris], is Bonsucro-certified cane sugar grown in Brazil and our [Reb M] facility with Amyris is literally next door to the cane sugar facility, so we're just pumping in that raw material, there's no transportation [of bulk sugars].”

Trusting the underlying data

He added: “In terms of comparing the big cane sugar countries, Brazil is one of one of the better options in terms of water availability, in terms of the land that's being utilized. But if you source sugar from a region that has water scarcity challenges or there is a lot of shipping to the end destination, those [LCA] numbers can move a lot.

“So I think ultimately, it's going to be about ingredient manufacturers, food and beverage manufacturers, doing their own LCAs with primary data and being transparent as much as possible so that we can really trust the underlying data.”

The LCA is currently undergoing peer review to achieve compliance with ISO standards, with full results available for public view shortly, said Callaghan.

“The peer review process is wrapping up and we should have ISO compliance completed by the end of August. After that our full LCA report will be published on our website. We will have to redact some proprietary information for competitive purposes, but it will be a very full report of all of our assumptions and the methodologies behind it.”

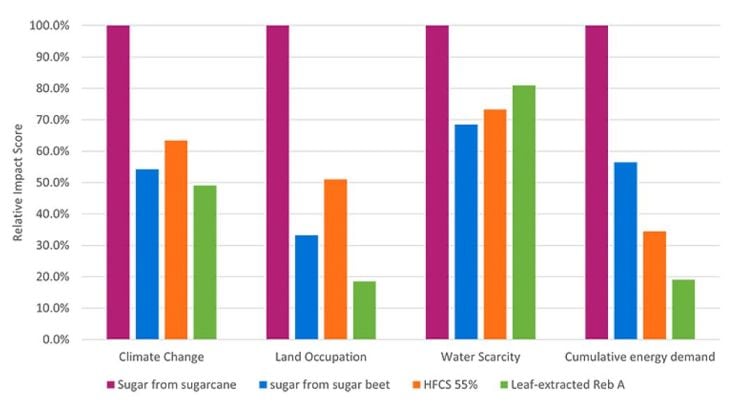

Ingredion has not yet released data comparing Reb M with sugar or high fructose corn syrup, although it has released the chart above comparing Reb A with these bulk sweeteners indicating that it outperforms them on all metrics except water scarcity.

But how useful is it to compare high intensity sweeteners such as stevia with bulk sweeteners such as sugar given that stevia is not a straight replacement for sugar in many applications, and frequently has to be combined with bulking agents, which have their own environmental footprint?

It’s a fair question, said Callaghan. “So every everything we did is on a sweetness equivalent basis, and Reb M is 300 times sweeter than sugar. For beverages you can do a one-to-one comparison between sugar and a high intensity sweetener, and beverages is the biggest market for these sweeteners.

“But you are correct as regards non-beverage applications where there’s what we call functional build-back, and [the environmental impact of any added] bulking ingredients should also be incorporated to get a true apples-to-apples comparison with sugar.”

Image credit: Ingredion